Page 235 - Separation process principles 2

P. 235

200 Chapter 6 Absorption and Stripping of Dilute Mixtures

1

Flexicerarnic

Mellapak Flexipac

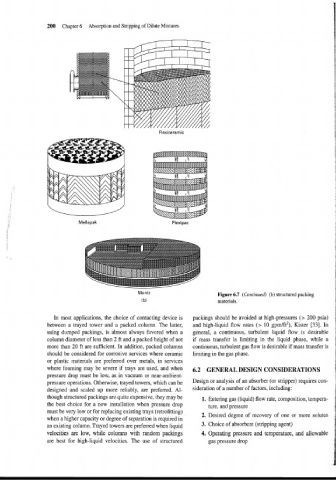

Montz Figure 6.7 (Continued) (b) structured packing

(b) materials.

In most applications, the choice of contacting device is paclungs should be avoided at high-pressures (> 200 psia)

between a trayed tower and a packed column. The latter, and high-liquid flow rates (> 10 gpm/ft2), aster [33]. In

using dumped packings, is almost always favored when a general, a continuous, turbulent liquid flow is desirable

column diameter of less than 2 ft and a packed height of not if mass transfer is limiting in the liquid phase, while a

more than 20 ft are sufficient. In addition, packed columns continuous, turbulent gas flow is desirable if mass transfer is

should be considered for corrosive services where ceramic limiting in the gas phase.

or plastic materials are preferred over metals, in services

where foaming may be severe if trays are used, and when 6.2 GENERAL DESIGN CONSIDERATIONS

pressure drop must be low, as in vacuum or near-ambient-

pressure operations. Otherwise, trayed towers, which can be Design or analysis of an absorber (or stripper) requires con-

designed and scaled up more reliably, are preferred. Al- sideration of a number of factors, including:

though structured packings are quite expensive, they may be 1. Entering gas (liquid) flow rate, composition, tempera-

the best choice for a new installation when pressure drop

ture, and pressure

must be very low or for replacing existing trays (retrofitting)

2. Desired degree of recovery of one or more solutes

when a higher capacity or degree of separation is required in

an existing column. Trayed towers are preferred when liquid 3. Choice of absorbent (stripping agent)

velocities are low, while columns with random packings 4, Operating pressure and temperature, and allowable

are best for high-liquid velocities. The use of structured gas pressure drop