Page 128 - Shigley's Mechanical Engineering Design

P. 128

bud29281_ch03_071-146.qxd 11/24/09 3:01PM Page 103 ntt 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Load and Stress Analysis 103

where H = power, hp

T = torque, lbf · in

n = shaft speed, rev/min

F = force, lbf

V = velocity, ft/min

When SI units are used, the equation is

H = Tω (3–43)

where H = power, W

T = torque, N · m

ω = angular velocity, rad/s

The torque T corresponding to the power in watts is given approximately by

H

T = 9.55 (3–44)

n

where n is in revolutions per minute.

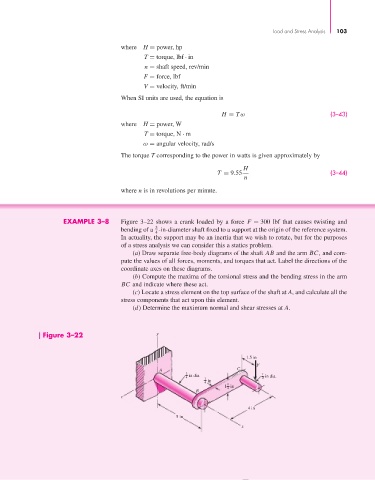

EXAMPLE 3–8 Figure 3–22 shows a crank loaded by a force F = 300 lbf that causes twisting and

3

bending of a -in-diameter shaft fixed to a support at the origin of the reference system.

4

In actuality, the support may be an inertia that we wish to rotate, but for the purposes

of a stress analysis we can consider this a statics problem.

(a) Draw separate free-body diagrams of the shaft AB and the arm BC, and com-

pute the values of all forces, moments, and torques that act. Label the directions of the

coordinate axes on these diagrams.

(b) Compute the maxima of the torsional stress and the bending stress in the arm

BC and indicate where these act.

(c) Locate a stress element on the top surface of the shaft at A, and calculate all the

stress components that act upon this element.

(d) Determine the maximum normal and shear stresses at A.

Figure 3–22 y

1.5 in

F

A C

3 in dia. 1 in dia.

4 2

1 in

4 1

1 in

4

B

z

4 in

5 in

x