Page 157 - Shigley's Mechanical Engineering Design

P. 157

bud29281_ch03_071-146.qxd 11/30/2009 5:34 pm Page 132 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

132 Mechanical Engineering Design

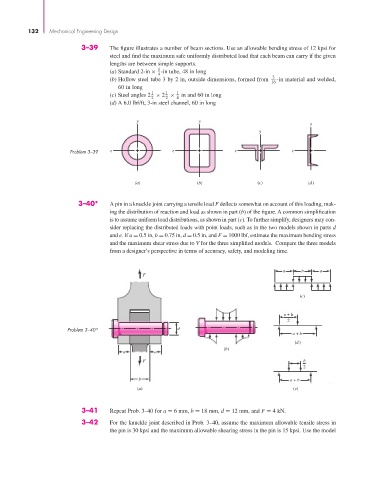

3–39 The figure illustrates a number of beam sections. Use an allowable bending stress of 12 kpsi for

steel and find the maximum safe uniformly distributed load that each beam can carry if the given

lengths are between simple supports.

1

(a) Standard 2-in × -in tube, 48 in long

4

(b) Hollow steel tube 3 by 2 in, outside dimensions, formed from 3 -in material and welded,

16

60 in long

1 1 1

(c) Steel angles 2 × 2 × in and 60 in long

2 2 4

(d) A 6.0 lbf/ft, 3-in steel channel, 60 in long

y y

y

y

Problem 3–39 z z z z

(a) (b) (c) (d)

3–40* A pin in a knuckle joint carrying a tensile load F deflects somewhat on account of this loading, mak-

ing the distribution of reaction and load as shown in part (b) of the figure. A common simplification

is to assume uniform load distributions, as shown in part (c). To further simplify, designers may con-

sider replacing the distributed loads with point loads, such as in the two models shown in parts d

and e. If a = 0.5 in, b = 0.75 in, d = 0.5 in, and F = 1000 lbf, estimate the maximum bending stress

and the maximum shear stress due to V for the three simplified models. Compare the three models

from a designer’s perspective in terms of accuracy, safety, and modeling time.

a b a

F

(c)

a + b b

2

Problem 3–40* d

a + b

(d)

(b)

a a

F b

2

b a + b

(a) (e)

3–41 Repeat Prob. 3–40 for a = 6 mm, b = 18 mm, d = 12 mm, and F = 4 kN.

3–42 For the knuckle joint described in Prob. 3–40, assume the maximum allowable tensile stress in

the pin is 30 kpsi and the maximum allowable shearing stress in the pin is 15 kpsi. Use the model