Page 160 - Shigley's Mechanical Engineering Design

P. 160

bud29281_ch03_071-146.qxd 11/30/2009 5:03 pm Page 135 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Load and Stress Analysis 135

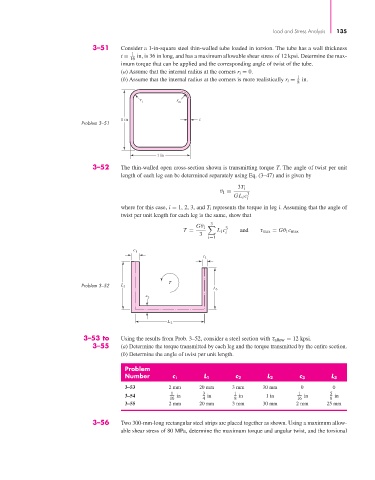

3–51 Consider a 1-in-square steel thin-walled tube loaded in torsion. The tube has a wall thickness

1

t = in, is 36 in long, and has a maximum allowable shear stress of 12 kpsi. Determine the max-

16

imum torque that can be applied and the corresponding angle of twist of the tube.

(a) Assume that the internal radius at the corners r i = 0.

1

(b) Assume that the internal radius at the corners is more realistically r i = in.

8

r i r m

1 in t

Problem 3–51

1 in

3–52 The thin-walled open cross-section shown is transmitting torque T. The angle of twist per unit

length of each leg can be determined separately using Eq. (3–47) and is given by

3T i

θ 1 = 3

GL i c

i

where for this case, i = 1, 2, 3, and T i represents the torque in leg i. Assuming that the angle of

twist per unit length for each leg is the same, show that

Gθ 1 3 3

T = L i c i and τ max = Gθ 1 c max

3

i=1

c

1

c 3

T

Problem 3–52 L 1

L 3

c

2

L 2

3–53 to Using the results from Prob. 3–52, consider a steel section with τ allow = 12 kpsi.

3–55 (a) Determine the torque transmitted by each leg and the torque transmitted by the entire section.

(b) Determine the angle of twist per unit length.

Problem

Number c 1 L 1 c 2 L 2 c 3 L 3

3–53 2 mm 20 mm 3 mm 30 mm 0 0

1 3 1 1 5

3–54 in in in 1 in in in

16 4 8 16 8

3–55 2 mm 20 mm 3 mm 30 mm 2 mm 25 mm

3–56 Two 300-mm-long rectangular steel strips are placed together as shown. Using a maximum allow-

able shear stress of 80 MPa, determine the maximum torque and angular twist, and the torsional