Page 324 - Shigley's Mechanical Engineering Design

P. 324

bud29281_ch06_265-357.qxd 11/30/2009 4:23 pm Page 299 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

Fatigue Failure Resulting from Variable Loading 299

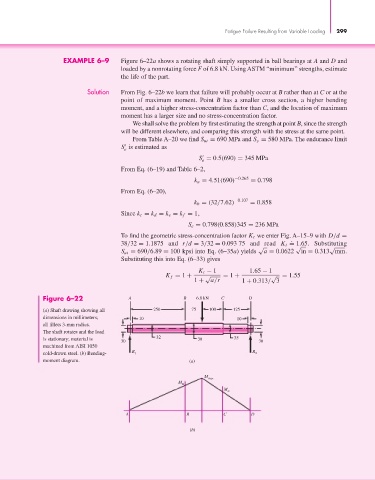

EXAMPLE 6–9 Figure 6–22a shows a rotating shaft simply supported in ball bearings at A and D and

loaded by a nonrotating force F of 6.8 kN. Using ASTM “minimum” strengths, estimate

the life of the part.

Solution From Fig. 6–22b we learn that failure will probably occur at B rather than at C or at the

point of maximum moment. Point B has a smaller cross section, a higher bending

moment, and a higher stress-concentration factor than C, and the location of maximum

moment has a larger size and no stress-concentration factor.

We shall solve the problem by first estimating the strength at point B, since the strength

will be different elsewhere, and comparing this strength with the stress at the same point.

From Table A–20 we find S ut = 690 MPa and S y = 580 MPa. The endurance limit

S is estimated as

e

S = 0.5(690) = 345 MPa

e

From Eq. (6–19) and Table 6–2,

k a = 4.51(690) −0.265 = 0.798

From Eq. (6–20),

k b = (32/7.62) −0.107 = 0.858

Since k c = k d = k e = k f = 1,

S e = 0.798(0.858)345 = 236 MPa

To find the geometric stress-concentration factor K t we enter Fig. A–15–9 with D/d =

.

38/32 = 1.1875 and r/d = 3/32 = 0.093 75 and read K t = 1.65. Substituting

√ √ √

S ut = 690/6.89 = 100 kpsi into Eq. (6–35a) yields a = 0.0622 in = 0.313 mm.

Substituting this into Eq. (6–33) gives

K t − 1 1.65 − 1

K f = 1 + √ = 1 + √ = 1.55

1 + a/r 1 + 0.313/ 3

Figure 6–22 A B 6.8 kN C D

(a) Shaft drawing showing all 250 75 100 125

dimensions in millimeters; 10 10

all fillets 3-mm radius.

The shaft rotates and the load

32 35

is stationary; material is 38

30 30

machined from AISI 1050

R R

cold-drawn steel. (b) Bending- 1 2

moment diagram. (a)

M max

M B

M

C

A B C D

(b)