Page 85 - Sustainability in the Process Industry Integration and Optimization

P. 85

62 Cha p te r F o u r

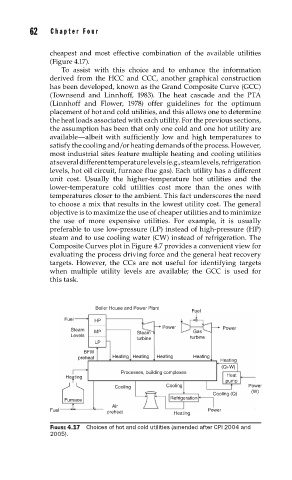

cheapest and most effective combination of the available utilities

(Figure 4.17).

To assist with this choice and to enhance the information

derived from the HCC and CCC, another graphical construction

has been developed, known as the Grand Composite Curve (GCC)

(Townsend and Linnhoff, 1983). The heat cascade and the PTA

(Linnhoff and Flower, 1978) offer guidelines for the optimum

placement of hot and cold utilities, and this allows one to determine

the heat loads associated with each utility. For the previous sections,

the assumption has been that only one cold and one hot utility are

available—albeit with sufficiently low and high temperatures to

satisfy the cooling and/or heating demands of the process. However,

most industrial sites feature multiple heating and cooling utilities

at several different temperature levels (e.g., steam levels, refrigeration

levels, hot oil circuit, furnace flue gas). Each utility has a different

unit cost. Usually the higher-temperature hot utilities and the

lower-temperature cold utilities cost more than the ones with

temperatures closer to the ambient. This fact underscores the need

to choose a mix that results in the lowest utility cost. The general

objective is to maximize the use of cheaper utilities and to minimize

the use of more expensive utilities. For example, it is usually

preferable to use low-pressure (LP) instead of high-pressure (HP)

steam and to use cooling water (CW) instead of refrigeration. The

Composite Curves plot in Figure 4.7 provides a convenient view for

evaluating the process driving force and the general heat recovery

targets. However, the CCs are not useful for identifying targets

when multiple utility levels are available; the GCC is used for

this task.

Boiler House and Power Plant

Fuel

Fuel HP

Power Power

Steam MP Steam Gas

Levels turbine

turbine

LP

BFW

preheat Heating Heating Heating Heating

Heating

(Q+W)

Processes, building complexes

Heating Heat

pump

Cooling Cooling Power

(W)

Cooling (Q)

Furnace Refrigeration

Air

Fuel preheat Heating Power

FIGURE 4.17 Choices of hot and cold utilities (amended after CPI 2004 and

2005).