Page 86 - Sustainability in the Process Industry Integration and Optimization

P. 86

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 63

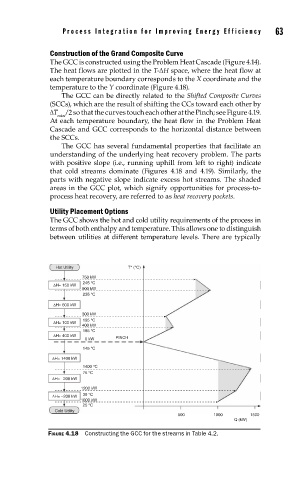

Construction of the Grand Composite Curve

The GCC is constructed using the Problem Heat Cascade (Figure 4.14).

The heat flows are plotted in the T-ΔH space, where the heat flow at

each temperature boundary corresponds to the X coordinate and the

temperature to the Y coordinate (Figure 4.18).

The GCC can be directly related to the Shifted Composite Curves

(SCCs), which are the result of shifting the CCs toward each other by

ΔT /2 so that the curves touch each other at the Pinch; see Figure 4.19.

min

At each temperature boundary, the heat flow in the Problem Heat

Cascade and GCC corresponds to the horizontal distance between

the SCCs.

The GCC has several fundamental properties that facilitate an

understanding of the underlying heat recovery problem. The parts

with positive slope (i.e., running uphill from left to right) indicate

that cold streams dominate (Figures 4.18 and 4.19). Similarly, the

parts with negative slope indicate excess hot streams. The shaded

areas in the GCC plot, which signify opportunities for process-to-

process heat recovery, are referred to as heat recovery pockets.

Utility Placement Options

The GCC shows the hot and cold utility requirements of the process in

terms of both enthalpy and temperature. This allows one to distinguish

between utilities at different temperature levels. There are typically

Hot Utility T* (°C)

750 kW

245 °C

ΔH= 150 kW

900 kW

235 °C

ΔH= 600 kW

300 kW

195 °C

ΔH= 100 kW

400 kW

185 °C

ΔH= 400 kW

0 kW PINCH

145 °C

ΔH= 1400 kW

1400 °C

75 °C

ΔH= −200 kW

1200 kW

35 °C

ΔH= −200 kW

1000 kW

25 °C

Cold Utility

500 1000 1500

Q (kW)

FIGURE 4.18 Constructing the GCC for the streams in Table 4.2.