Page 90 - Sustainability in the Process Industry Integration and Optimization

P. 90

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 67

then combining it with flue gas reduces the latter’s CP and the

corresponding stack heat losses.

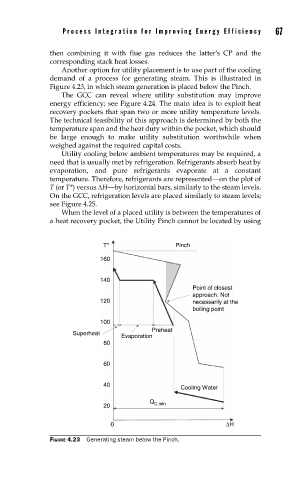

Another option for utility placement is to use part of the cooling

demand of a process for generating steam. This is illustrated in

Figure 4.23, in which steam generation is placed below the Pinch.

The GCC can reveal where utility substitution may improve

energy efficiency; see Figure 4.24. The main idea is to exploit heat

recovery pockets that span two or more utility temperature levels.

The technical feasibility of this approach is determined by both the

temperature span and the heat duty within the pocket, which should

be large enough to make utility substitution worthwhile when

weighed against the required capital costs.

Utility cooling below ambient temperatures may be required, a

need that is usually met by refrigeration. Refrigerants absorb heat by

evaporation, and pure refrigerants evaporate at a constant

temperature. Therefore, refrigerants are represented—on the plot of

T (or T*) versus ΔH—by horizontal bars, similarly to the steam levels.

On the GCC, refrigeration levels are placed similarly to steam levels;

see Figure 4.25.

When the level of a placed utility is between the temperatures of

a heat recovery pocket, the Utility Pinch cannot be located by using

T* Pinch

160

140

Point of closest

approach. Not

120 necessarily at the

boiling point

100

Preheat

Superheat

Evaporation

80

60

40

Cooling Water

Q

20 C,min

0 ΔH

FIGURE 4.23 Generating steam below the Pinch.