Page 92 - Sustainability in the Process Industry Integration and Optimization

P. 92

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 69

(a) T* (b) T

HP steam

HP steam

LP steam LP steam

LP steam Pinch

Process Pinch Process Pinch LP steam

Pinch

CW

CW

ΔH ΔH

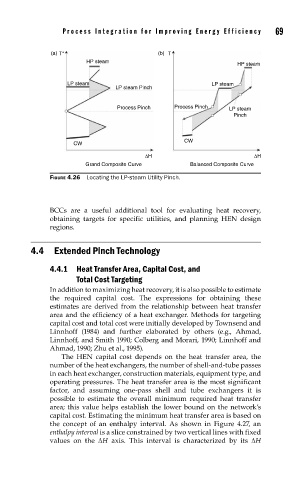

Grand Composite Curve Balanced Composite Curve

FIGURE 4.26 Locating the LP-steam Utility Pinch.

BCCs are a useful additional tool for evaluating heat recovery,

obtaining targets for specific utilities, and planning HEN design

regions.

4.4 Extended Pinch Technology

4.4.1 Heat Transfer Area, Capital Cost, and

Total Cost Targeting

In addition to maximizing heat recovery, it is also possible to estimate

the required capital cost. The expressions for obtaining these

estimates are derived from the relationship between heat transfer

area and the efficiency of a heat exchanger. Methods for targeting

capital cost and total cost were initially developed by Townsend and

Linnhoff (1984) and further elaborated by others (e.g., Ahmad,

Linnhoff, and Smith 1990; Colberg and Morari, 1990; Linnhoff and

Ahmad, 1990; Zhu et al., 1995).

The HEN capital cost depends on the heat transfer area, the

number of the heat exchangers, the number of shell-and-tube passes

in each heat exchanger, construction materials, equipment type, and

operating pressures. The heat transfer area is the most significant

factor, and assuming one-pass shell and tube exchangers it is

possible to estimate the overall minimum required heat transfer

area; this value helps establish the lower bound on the network’s

capital cost. Estimating the minimum heat transfer area is based on

the concept of an enthalpy interval. As shown in Figure 4.27, an

enthalpy interval is a slice constrained by two vertical lines with fixed

values on the ΔH axis. This interval is characterized by its ΔH