Page 95 - Sustainability in the Process Industry Integration and Optimization

P. 95

72 Cha p te r F o u r

A + W

T* T* A

A–(Q–W) Q

100% conversion

Heat→Work

PINCH

Q–W HE W Q

PINCH HE W

100% conversion Q–W

B Heat→Work B–Q

Integration above the pinch Integration below the pinch

(a) (b)

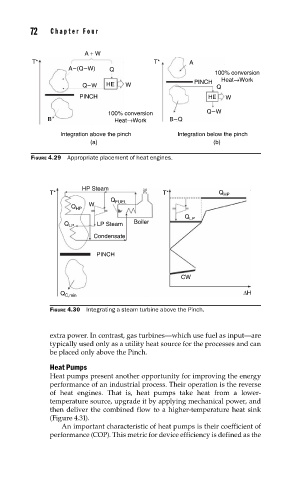

FIGURE 4.29 Appropriate placement of heat engines.

HP Steam

T* T* Q HP

Q FUEL

Q HP W

Q LP

Q LP LP Steam Boiler

Condensate

PINCH

CW

Q C,min ΔH

FIGURE 4.30 Integrating a steam turbine above the Pinch.

extra power. In contrast, gas turbines—which use fuel as input—are

typically used only as a utility heat source for the processes and can

be placed only above the Pinch.

Heat Pumps

Heat pumps present another opportunity for improving the energy

performance of an industrial process. Their operation is the reverse

of heat engines. That is, heat pumps take heat from a lower-

temperature source, upgrade it by applying mechanical power, and

then deliver the combined flow to a higher-temperature heat sink

(Figure 4.31).

An important characteristic of heat pumps is their coefficient of

performance (COP). This metric for device efficiency is defined as the