Page 98 - Sustainability in the Process Industry Integration and Optimization

P. 98

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 75

ΔT MIN = 20°C

ΔH[MW] T*[°C]

21.90 440 500

450

29.40 410

400

23.82 131 350

18.00 118 300

T*[°C] 250

1.80 115

200

0.00 94 150

4.30 91 100

50

11.50 79

0

15.00 30 0 10 20 30 40

ΔH [MW]

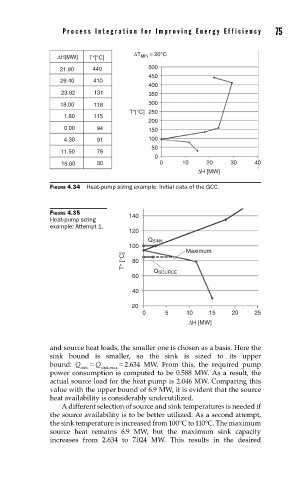

FIGURE 4.34 Heat-pump sizing example: Initial data of the GCC.

FIGURE 4.35 140

Heat-pump sizing

example: Attempt 1.

120

Q SINK

100

Maximum

T* [°C] 80

Q SOURCE

60

40

20

0 5 10 15 20 25

ΔH [MW]

and source heat loads, the smaller one is chosen as a basis. Here the

sink bound is smaller, so the sink is sized to its upper

bound: Q = Q = 2.634 MW. From this, the required pump

sink sink,max

power consumption is computed to be 0.588 MW. As a result, the

actual source load for the heat pump is 2.046 MW. Comparing this

value with the upper bound of 6.9 MW, it is evident that the source

heat availability is considerably underutilized.

A different selection of source and sink temperatures is needed if

the source availability is to be better utilized. As a second attempt,

the sink temperature is increased from 100°C to 110°C. The maximum

source heat remains 6.9 MW, but the maximum sink capacity

increases from 2.634 to 7.024 MW. This results in the desired