Page 94 - Sustainability in the Process Industry Integration and Optimization

P. 94

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 71

4.4.2 Heat Integration of Energy-Intensive Processes

Heat Engines

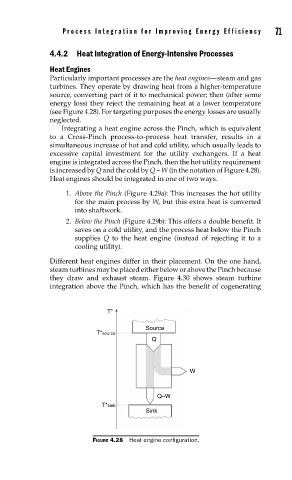

Particularly important processes are the heat engines—steam and gas

turbines. They operate by drawing heat from a higher-temperature

source, converting part of it to mechanical power; then (after some

energy loss) they reject the remaining heat at a lower temperature

(see Figure 4.28). For targeting purposes the energy losses are usually

neglected.

Integrating a heat engine across the Pinch, which is equivalent

to a Cross-Pinch process-to-process heat transfer, results in a

simultaneous increase of hot and cold utility, which usually leads to

excessive capital investment for the utility exchangers. If a heat

engine is integrated across the Pinch, then the hot utility requirement

is increased by Q and the cold by Q − W (in the notation of Figure 4.28).

Heat engines should be integrated in one of two ways.

1. Above the Pinch (Figure 4.29a): This increases the hot utility

for the main process by W, but this extra heat is converted

into shaftwork.

2. Below the Pinch (Figure 4.29b): This offers a double benefit. It

saves on a cold utility, and the process heat below the Pinch

supplies Q to the heat engine (instead of rejecting it to a

cooling utility).

Different heat engines differ in their placement. On the one hand,

steam turbines may be placed either below or above the Pinch because

they draw and exhaust steam. Figure 4.30 shows steam turbine

integration above the Pinch, which has the benefit of cogenerating

T*

Source

T*source

Q

W

Q–W

T*sink

Sink

FIGURE 4.28 Heat engine confi guration.