Page 109 - The Art and Science of Analog Circuit Design

P. 109

One Trip Down the 1C Development Road

steering transistors are also at a 10:1 ratio. But the small signal steering is

set by the ratio of the sum of the r e and the bulk resistance in each transis-

tor, and in this case the result is a 6.33:1 ratio!

In the fader circuit, the only way to improve the gain accuracy is with

low R b and R e steering transistors. Unfortunately this requires larger tran-

sistors running at low current densities and that significantly reduces the

speed (F-tau) of the current steering devices. I went back to the simpler

circuit of Figure 8-5, increased the size of the current steering transis-

tors, and tweaked the compensation capacitor and feedback resistors to

optimize the response.

Now it was time to find a way to interface the external control sig-

nal(s) to the pre-distortion diodes of Figure 8-5. The incoming signal

would have to be converted to a current to drive the pre-distortion diodes,

Ql and Q3. A replica of that current would have to be subtracted from

a fixed DC current and the result would drive the other pre-distortion

diodes, Q2 and Q4.

I did not want to include an absolute reference in this product for sev-

eral reasons. An internal reference would have to be available for the ex-

ternal control circuitry to use, in order not to increase the errors caused by

multiple references. Therefore it would have to be capable of significant

output drive and tolerant of unusual loading. In short, the internal refer-

ence would have to be as good as a standard reference. The inaccuracy of

an internal reference would add to the part-to-part variations unless it was

trimmed to a very accurate value. Both of these requirements would in-

crease the die size and/or the pin count of the 1C. Lastly, there is no stan-

dard for the incoming signals, so what value should the reference be?

I decided to require that an external reference, or "full scale" voltage,

would be applied to the part. With an external full scale and control volt-

age, I could use identical circuits to convert the two voltages into two

currents. The value of the full scale voltage is not critical because only

the ratio between it and the control voltage matters. With the same circuit

being used for both converters, the ratio matching should be excellent.

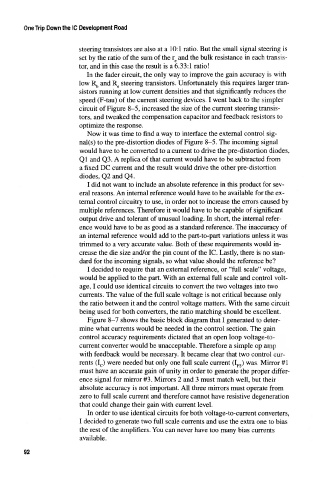

Figure 8-7 shows the basic block diagram that I generated to deter-

mine what currents would be needed in the control section. The gain

control accuracy requirements dictated that an open loop voltage-to~

current converter would be unacceptable. Therefore a simple op amp

with feedback would be necessary. It became clear that two control cur-

rents (I c) were needed but only one full scale current (I FS) was. Mirror #1

must have an accurate gain of unity in order to generate the proper differ-

ence signal for mirror #3. Mirrors 2 and 3 must match well, but their

absolute accuracy is not important. All three mirrors must operate from

zero to full scale current and therefore cannot have resistive degeneration

that could change their gain with current level.

In order to use identical circuits for both voltage-to-current converters,

I decided to generate two full scale currents and use the extra one to bias

the rest of the amplifiers. You can never have too many bias currents

available.

92