Page 66 -

P. 66

. . . . System Hydraulics

multiplied by the Velocity Head (from the Friction Loss tables) to

provide the Friction Loss for that particular fitting. Consequently, the

value of the friction loss for each fitting must be calculated individually.

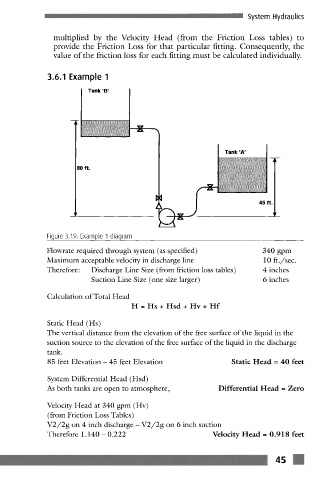

3.6.1 Example 1

Tank 'B'

X

Tank 'A'

80 ft.

q~e

45 f

Figure 3.19: Example 1 diagram

Flowrate required through system (as specified) 340 gpm

Maximum acceptable velocity in discharge line 10 ft./sec.

Therefore: Discharge Line Size (from friction loss tables) 4 inches

Suction Line Size (one size larger) 6 inches

Calculation of Total Head

H = Hs + Hsd + Hv + Hf

Static Head (Hs)

The vertical distance from the elevation of the free surface of the liquid in the

suction source to the elevation of the free surface of the liquid in the discharge

tank.

85 feet Elevation- 45 feet Elevation Static Head = 40 feet

System Differential Head (Hsd)

As both tanks are open to atmosphere, Differential Head = Zero

Velocity Head at 340 gpm (Hv)

(from Friction Loss Tables)

V2/2g on 4 inch discharge- V2/2g on 6 inch suction

Therefore 1.140- 0.222 Velocity Head -- 0.918 feet