Page 63 -

P. 63

The Practical Pumping Handbook :ii:i: -iiiiii : :: : :iiiiiii:i iiiiiiiiiii::ii:: ii:iiii:i-iiiii ....... i ........ i ............. ,i-i ........ ii-i .......... i ........

system, and can be achieved by a variety of mechanical or electrical

drives. The Variable Frequency Drive is one of the most commonly

used items in many plants.

When frequent adjustment is needed to the output of the pump, the

traditional method of throttling the discharge valve absorbs a significant

amount of friction which translates into energy losses that can be

identified in increased heat and excessive wear in the valve. It also

restrains the pump to operate at a lower and (usually) a less efficient

point on the performance curve, thus compounding the energy loss.

A speed reduction to lower the pump output will frequently have the

pump operating with only a very minor reduction in efficiency.

Computer controlled speed change systems are now available that

permits the end user to preset the required pumping condition (either

flow rate or head) and the Variable Frequency Drive will adjust the

pump speed automatically to meet all changes in system demand.

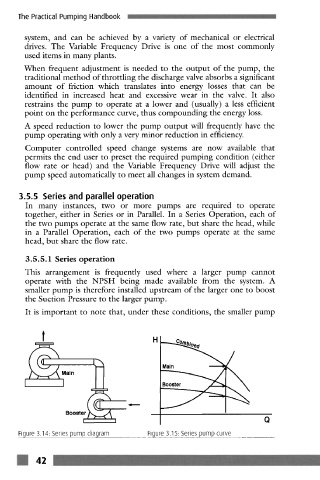

3.5.5 Series and parallel operation

In many instances, two or more pumps are required to operate

together, either in Series or in Parallel. In a Series Operation, each of

the two pumps operate at the same flow rate, but share the head, while

in a Parallel Operation, each of the two pumps operate at the same

head, but share the flow rate.

3.5.5.1 Series operation

This arrangement is frequently used where a larger pump cannot

operate with the NPSH being made available from the system. A

smaller pump is therefore installed upstream of the larger one to boost

the Suction Pressure to the larger pump.

It is important to note that, under these conditions, the smaller pump

Main

Booster

Q

Figure 3.14: Series pump diagram Figure 3.15: Series pump curve

m 42