Page 614 - The Mechatronics Handbook

P. 614

0066_Frame_C20 Page 84 Wednesday, January 9, 2002 5:49 PM

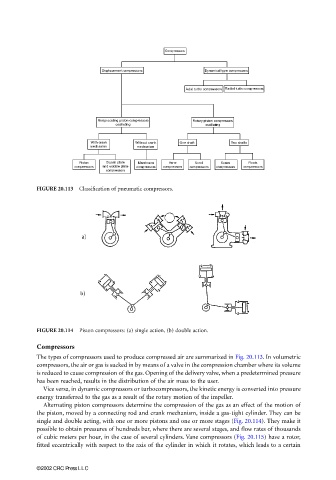

FIGURE 20.113 Classification of pneumatic compressors.

FIGURE 20.114 Piston compressors: (a) single action, (b) double action.

Compressors

The types of compressors used to produce compressed air are summarized in Fig. 20.113. In volumetric

compressors, the air or gas is sucked in by means of a valve in the compression chamber where its volume

is reduced to cause compression of the gas. Opening of the delivery valve, when a predetermined pressure

has been reached, results in the distribution of the air mass to the user.

Vice versa, in dynamic compressors or turbocompressors, the kinetic energy is converted into pressure

energy transferred to the gas as a result of the rotary motion of the impeller.

Alternating piston compressors determine the compression of the gas as an effect of the motion of

the piston, moved by a connecting rod and crank mechanism, inside a gas-tight cylinder. They can be

single and double acting, with one or more pistons and one or more stages (Fig. 20.114). They make it

possible to obtain pressures of hundreds bar, where there are several stages, and flow rates of thousands

of cubic meters per hour, in the case of several cylinders. Vane compressors (Fig. 20.115) have a rotor,

fitted eccentrically with respect to the axis of the cylinder in which it rotates, which leads to a certain

©2002 CRC Press LLC