Page 616 - The Mechatronics Handbook

P. 616

0066_Frame_C20 Page 86 Wednesday, January 9, 2002 5:49 PM

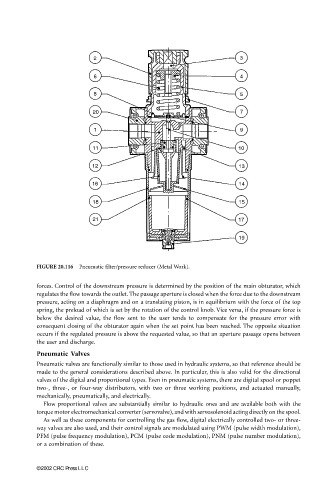

FIGURE 20.116 Pneumatic filter/pressure reducer (Metal Work).

forces. Control of the downstream pressure is determined by the position of the main obturator, which

regulates the flow towards the outlet. The passage aperture is closed when the force due to the downstream

pressure, acting on a diaphragm and on a translating piston, is in equilibrium with the force of the top

spring, the preload of which is set by the rotation of the control knob. Vice versa, if the pressure force is

below the desired value, the flow sent to the user tends to compensate for the pressure error with

consequent closing of the obturator again when the set point has been reached. The opposite situation

occurs if the regulated pressure is above the requested value, so that an aperture passage opens between

the user and discharge.

Pneumatic Valves

Pneumatic valves are functionally similar to those used in hydraulic systems, so that reference should be

made to the general considerations described above. In particular, this is also valid for the directional

valves of the digital and proportional types. Even in pneumatic systems, there are digital spool or poppet

two-, three-, or four-way distributors, with two or three working positions, and actuated manually,

mechanically, pneumatically, and electrically.

Flow proportional valves are substantially similar to hydraulic ones and are available both with the

torque motor electromechanical converter (servovalve), and with servosolenoid acting directly on the spool.

As well as these components for controlling the gas flow, digital electrically controlled two- or three-

way valves are also used, and their control signals are modulated using PWM (pulse width modulation),

PFM (pulse frequency modulation), PCM (pulse code modulation), PNM (pulse number modulation),

or a combination of these.

©2002 CRC Press LLC