Page 618 - The Mechatronics Handbook

P. 618

0066_Frame_C20 Page 88 Wednesday, January 9, 2002 5:49 PM

FIGURE 20.118 PWM (pulse width modulation) digital valves: (a) flow regulator, (b) pressure regulator.

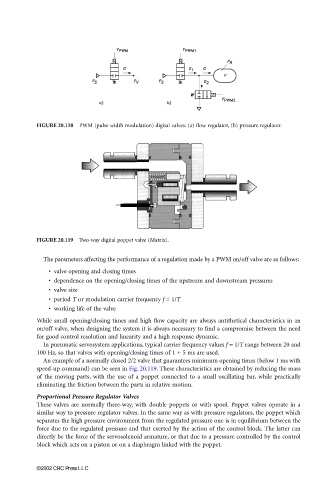

FIGURE 20.119 Two-way digital poppet valve (Matrix).

The parameters affecting the performance of a regulation made by a PWM on/off valve are as follows:

• valve opening and closing times

• dependence on the opening/closing times of the upstream and downstream pressures

• valve size

• period T or modulation carrier frequency f = 1/T

• working life of the valve

While small opening/closing times and high flow capacity are always antithetical characteristics in an

on/off valve, when designing the system it is always necessary to find a compromise between the need

for good control resolution and linearity and a high response dynamic.

In pneumatic servosystem applications, typical carrier frequency values f = 1/T range between 20 and

100 Hz, so that valves with opening/closing times of 1 ÷ 5 ms are used.

An example of a normally closed 2/2 valve that guarantees minimum opening times (below 1 ms with

speed-up command) can be seen in Fig. 20.119. These characteristics are obtained by reducing the mass

of the moving parts, with the use of a poppet connected to a small oscillating bar, while practically

eliminating the friction between the parts in relative motion.

Proportional Pressure Regulator Valves

These valves are normally three-way, with double poppets or with spool. Poppet valves operate in a

similar way to pressure regulator valves. In the same way as with pressure regulators, the poppet which

separates the high pressure environment from the regulated pressure one is in equilibrium between the

force due to the regulated pressure and that exerted by the action of the control block. The latter can

directly be the force of the servosolenoid armature, or that due to a pressure controlled by the control

block which acts on a piston or on a diaphragm linked with the poppet.

©2002 CRC Press LLC