Page 143 - Theory and Design of Air Cushion Craft

P. 143

126 Steady drag forces

outer

inner

(a)

outer

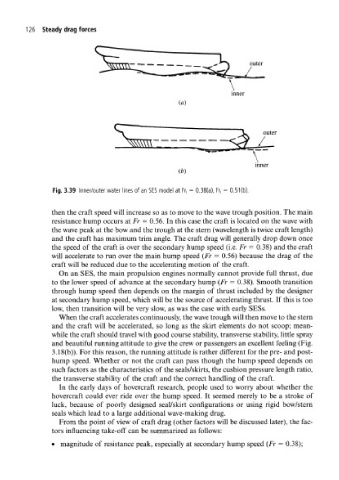

Fig. 3.39 Inner/outer water lines of an'SES model at Fr, = 0.38(a), Fr, = 0.51(b).

then the craft speed will increase so as to move to the wave trough position. The main

resistance hump occurs at Fr = 0.56. In this case the craft is located on the wave with

the wave peak at the bow and the trough at the stern (wavelength is twice craft length)

and the craft has maximum trim angle. The craft drag will generally drop down once

the speed of the craft is over the secondary hump speed (i.e. Fr = 0.38) and the craft

will accelerate to run over the main hump speed (Fr = 0.56) because the drag of the

craft will be reduced due to the accelerating motion of the craft.

On an SES, the main propulsion engines normally cannot provide full thrust, due

to the lower speed of advance at the secondary hump (Fr = 0.38). Smooth transition

through hump speed then depends on the margin of thrust included by the designer

at secondary hump speed, which will be the source of accelerating thrust. If this is too

low, then transition will be very slow, as was the case with early SESs.

When the craft accelerates continuously, the wave trough will then move to the stem

and the craft will be accelerated, so long as the skirt elements do not scoop; mean-

while the craft should travel with good course stability, transverse stability, little spray

and beautiful running attitude to give the crew or passengers an excellent feeling (Fig.

3.18(b)). For this reason, the running attitude is rather different for the pre- and post-

hump speed. Whether or not the craft can pass though the hump speed depends on

such factors as the characteristics of the seals/skirts, the cushion pressure length ratio,

the transverse stability of the craft and the correct handling of the craft.

In the early days of hovercraft research, people used to worry about whether the

hovercraft could ever ride over the hump speed. It seemed merely to be a stroke of

luck, because of poorly designed seal/skirt configurations or using rigid bow/stern

seals which lead to a large additional wave-making drag.

From the point of view of craft drag (other factors will be discussed later), the fac-

tors influencing take-off can be summarized as follows:

• magnitude of resistance peak, especially at secondary hump speed (Fr = 0.38);