Page 249 - Fluid Power Engineering

P. 249

216 Chapter Te n

Asynchronous

generator Capacitor for

reactive power

Gear

Grid

box

Soft starter Transformer

Turbine

Variable

resistance

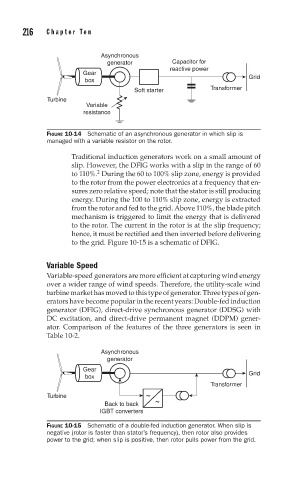

FIGURE 10-14 Schematic of an asynchronous generator in which slip is

managed with a variable resistor on the rotor.

Traditional induction generators work on a small amount of

slip. However, the DFIG works with a slip in the range of 60

2

to 110%. During the 60 to 100% slip zone, energy is provided

to the rotor from the power electronics at a frequency that en-

sures zero relative speed; note that the stator is still producing

energy. During the 100 to 110% slip zone, energy is extracted

from the rotor and fed to the grid. Above 110%, the blade pitch

mechanism is triggered to limit the energy that is delivered

to the rotor. The current in the rotor is at the slip frequency;

hence, it must be rectified and then inverted before delivering

to the grid. Figure 10-15 is a schematic of DFIG.

Variable Speed

Variable-speed generators are more efficient at capturing wind energy

over a wider range of wind speeds. Therefore, the utility-scale wind

turbine market has moved to this type of generator. Three types of gen-

erators have become popular in the recent years: Double-fed induction

generator (DFIG), direct-drive synchronous generator (DDSG) with

DC excitation, and direct-drive permanent magnet (DDPM) gener-

ator. Comparison of the features of the three generators is seen in

Table 10-2.

Asynchronous

generator

Gear

box Grid

Transformer

Turbine ~

Back to back ~

IGBT converters

FIGURE 10-15 Schematic of a double-fed induction generator. When slip is

negative (rotor is faster than stator’s frequency), then rotor also provides

power to the grid; when slip is positive, then rotor pulls power from the grid.