Page 445 - Wind Energy Handbook

P. 445

PITCH BEARINGS 419

The stress distributions calculated for blade root fixings are subject to significant

levels of uncertainty, so it is normal to conduct both static and fatigue tests on them

to verify the suitability of the design. Static pull-out failures of carrot connectors

occur as a result of shearing of the wood surrounding the grout, but fatigue failures

can also occur in the connector itself or the grout. However, SGI studs subjected to

R ¼ 0:1 fatigue loading at over 60 percent of the UTS have survived for approxi-

6

mately 10 cycles.

Mayer (1996) records the results of fatigue tests on the other blade root fixings

featured in Figure 7.19, but in no case did failure occur as a result of fatigue of the

GFRP in the region of the root fixing. In the case of the T-bolt fixing arrangement,

failure occurred in the studs rather than in the GRP. The pin-hole flange specimens

developed fatigue cracks in the GFRP in areas remote from the root fixings and the

trumpet flange specimens developed cracks in the flanges themselves.

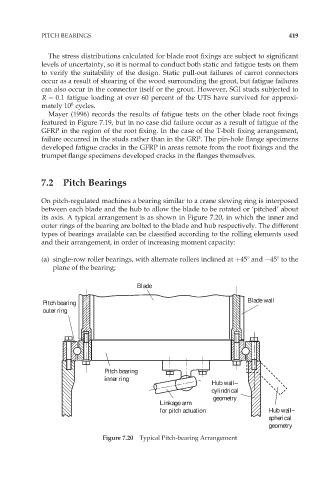

7.2 Pitch Bearings

On pitch-regulated machines a bearing similar to a crane slewing ring is interposed

between each blade and the hub to allow the blade to be rotated or ‘pitched’ about

its axis. A typical arrangement is as shown in Figure 7.20, in which the inner and

outer rings of the bearing are bolted to the blade and hub respectively. The different

types of bearings available can be classified according to the rolling elements used

and their arrangement, in order of increasing moment capacity:

(a) single-row roller bearings, with alternate rollers inclined at þ458 and 458 to the

plane of the bearing;

Blade

Blade wall

Pitch bearing

outer ring

Pitch bearing

inner ring

Hub wall–

cylindrical

geometry

Linkage arm

for pitch actuation Hub wall–

spherical

geometry

Figure 7.20 Typical Pitch-bearing Arrangement