Page 115 - Wire Bonding in Microelectronics

P. 115

94 Cha pte r F o u r

Wire

Shoulder

Bonded ball

chip Shear F

tool

Bonding pad

Area of contact

(faying surface)

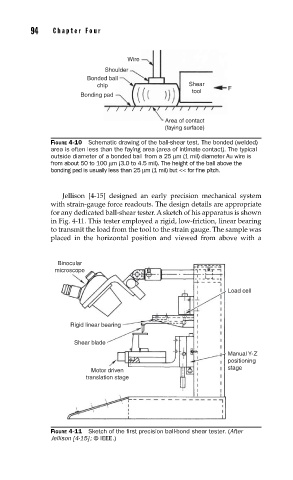

FIGURE 4-10 Schematic drawing of the ball-shear test. The bonded (welded)

area is often less than the faying area (area of intimate contact). The typical

outside diameter of a bonded ball from a 25 µm (1 mil) diameter Au wire is

from about 50 to 100 µm (3.0 to 4.5 mil). The height of the ball above the

bonding pad is usually less than 25 µm (1 mil) but << for fi ne pitch.

Jellison [4-15] designed an early precision mechanical system

with strain-gauge force readouts. The design details are appropriate

for any dedicated ball-shear tester. A sketch of his apparatus is shown

in Fig. 4-11. This tester employed a rigid, low-friction, linear bearing

to transmit the load from the tool to the strain gauge. The sample was

placed in the horizontal position and viewed from above with a

Binocular

microscope

Load cell

Rigid linear bearing

Shear blade

Manual Y-Z

positioning

stage

Motor driven

translation stage

FIGURE 4-11 Sketch of the fi rst precision ball-bond shear tester. (After

Jellison [4-15] ; © IEEE.)