Page 118 - Wire Bonding in Microelectronics

P. 118

W ir e Bond Testing 97

A manual shear probe is never used to obtain quantitative data. It

is primarily used to quickly set up a manual bonder on the machine,

for bonding one-of-a-kind experimental systems/chips (done often

in R&D laboratories, but never in production areas). Such manual

probes cannot be used for fine-pitch ball bond evaluation.

4.3.4 Interferences to Making Accurate

Ball-Shear Test Measurements

As with any test method, there may be problems in performing the

ball-shear test that can produce incorrect or misleading data. The

general ball-shear test failure modes are given in App. 4A [4-47].

Others are summarized below:

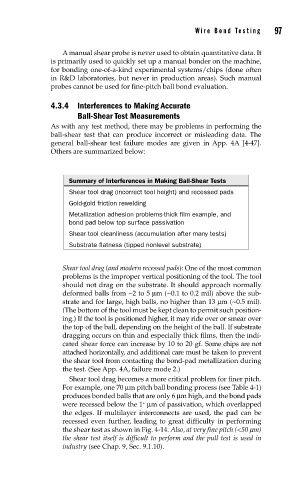

Summary of Interferences in Making Ball-Shear Tests

Shear tool drag (incorrect tool height) and recessed pads

Gold-gold friction rewelding

Metallization adhesion problems-thick film example, and

bond pad below top surface passivation

Shear tool cleanliness (accumulation after many tests)

Substrate flatness (tipped nonlevel substrate)

Shear tool drag (and modern recessed pads): One of the most common

problems is the improper vertical positioning of the tool. The tool

should not drag on the substrate. It should approach normally

deformed balls from ~2 to 5 µm (~0.1 to 0.2 mil) above the sub-

strate and for large, high balls, no higher than 13 µm (~0.5 mil).

(The bottom of the tool must be kept clean to permit such position-

ing.) If the tool is positioned higher, it may ride over or smear over

the top of the ball, depending on the height of the ball. If substrate

dragging occurs on thin and especially thick films, then the indi-

cated shear force can increase by 10 to 20 gf. Some chips are not

attached horizontally, and additional care must be taken to prevent

the shear tool from contacting the bond-pad metallization during

the test. (See App. 4A, failure mode 2.)

Shear tool drag becomes a more critical problem for finer pitch.

For example, one 70 µm pitch ball bonding process (see Table 4-1)

produces bonded balls that are only 6 µm high, and the bond pads

+

were recessed below the 1 µm of passivation, which overlapped

the edges. If multilayer interconnects are used, the pad can be

recessed even further, leading to great difficulty in performing

the shear test as shown in Fig. 4-14. Also, at very fine pitch (<50 mm)

the shear test itself is difficult to perform and the pull test is used in

industry (see Chap. 9, Sec. 9.1.10).