Page 121 - Wire Bonding in Microelectronics

P. 121

100 Cha pte r F o u r

shear test evaluation of compound-thermosonic bonds [4-24].This

work found that centering of the top ball bond on the bottom ball

was very important. There was an increased tendency to crater

in cases where the top ball bond was misaligned on the bottom

one (as revealed by the ball-shear test). Some bonding machines

resulted in more craters than others without apparent reason.

Increased ultrasonic energy also significantly increased crater-

ing, which is normally to be expected. However, when ball on ball

cratering occurred, the energy could be minimized (also tempera-

ture increased) and essentially cure the cratering problem. When

optimized, the bond shear force of the lower ball was statistically

unchanged from that of a single ball bond. Therefore, the use of

compound bonds on chips, made with manual bonders, should

be minimized. Autobonders precisely center a ball on a ball, and

craters from them have not been observed. Stacked ball bonds

made by autobonders are used in making compound ball bonds for

use as standoff bumps when converting devices with Al bond pads

into flip chips (ball bumped flip chips). In most cases, only one ball

bond is used, but there are examples of stacking several to obtain

increased height [4-24]. This offers stress relief against fatigue fail-

ure in thermal cycling (see Fig. 4-16). These stacked bonds applied

with autobonders would be well centered on one another. As such,

they do not pose cratering problems. However, the correct procedure

for shear test evaluation of the stacked bonds is not obvious. Most

likely, the Au-Au bond interfaces will be strong and cause no reli-

ability problems (see Chap. 5), so testing the lower (Au-Al) interface

alone should be suffi cient.

(a) (b)

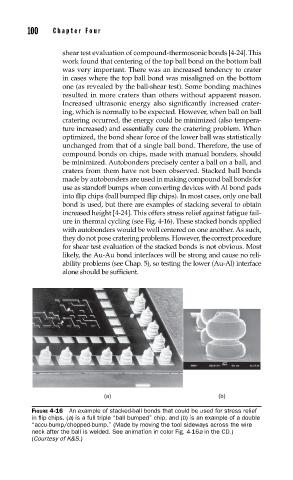

FIGURE 4-16 An example of stacked-ball bonds that could be used for stress relief

in fl ip chips. (a) is a full triple “ball bumped” chip, and (b) is an example of a double

“accu-bump/chopped-bump.” (Made by moving the tool sideways across the wire

neck after the ball is welded. See animation in color Fig. 4-16a in the CD.)

(Courtesy of K&S.)