Page 124 - Wire Bonding in Microelectronics

P. 124

lm Process,

70

Process,

lm

80

lm

90

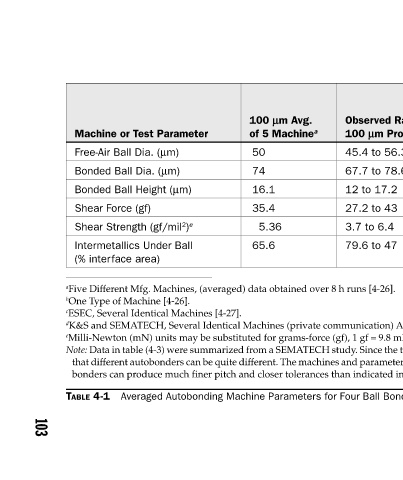

Observed Range, 1 type of 1 type of Process 1 type Machine d Machine c of Machine b lm Process a 100 40.6 43.2 _ 45.4 to 56.3 47 55.8 61.3 67.7 to 78.6 5.9 12.5 13.5 12 to 17.2 19.2 25.7 32.4 27.2 to 43 7.04 6.5 7.06 3.7 to 6.4 >80 79.5 _ 79.6 to 47 e Milli-Newton (m

lm Avg. of 5 Machine a

100 50 74 16.1 35.4 5.36 65.6 a Five Different Mfg. Machines, (averaged) data obtained over 8 h runs [4-26]. d K&S and SEMATECH, Several Identical Machines (private communication) Also see [4-28]. bonders can produce much finer pitch and closer tolerances than indicated in this table

Machine or Test Parameter Free-Air Ball Dia. (µm) Bonded Ball Dia. (µm) Bonded Ball Height (µm) Shear Force (gf) Shear Strength (gf/mil 2 ) e Intermetallics Under Ball (% interface area) b One Type of Machine [4-26]. c ESEC, Several Identical Machines [4-27].

TABLE 4-1

103