Page 218 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 218

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap14 Final Proof page 214 3.1.2007 9:10pm Compositor Name: SJoearun

14/214 ARTIFICIAL LIFT METHODS

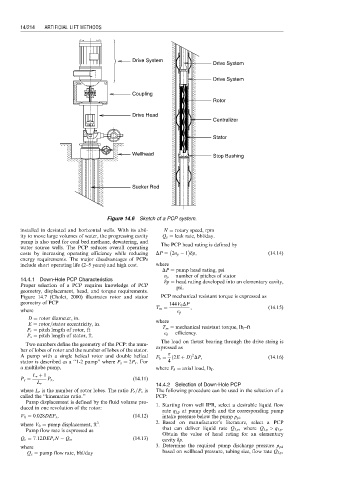

Drive System

Drive System

Drive System

Coupling

Rotor

Drive Head

Centralizer

Stator

Wellhead Stop Bushing

Sucker Rod

Figure 14.6 Sketch of a PCP system.

installed in deviated and horizontal wells. With its abil- N ¼ rotary speed, rpm

ity to move large volumes of water, the progressing cavity Q s ¼ leak rate, bbl/day.

pump is also used for coal bed methane, dewatering, and The PCP head rating is defined by

water source wells. The PCP reduces overall operating

costs by increasing operating efficiency while reducing DP ¼ 2n p 1 dp, (14:14)

energy requirements. The major disadvantages of PCPs

include short operating life (2–5 years) and high cost. where

DP ¼ pump head rating, psi

n p ¼ number of pitches of stator

14.4.1 Down-Hole PCP Characteristics dp ¼ head rating developed into an elementary cavity,

Proper selection of a PCP requires knowledge of PCP psi.

geometry, displacement, head, and torque requirements.

Figure 14.7 (Cholet, 2000) illustrates rotor and stator PCP mechanical resistant torque is expressed as

geometry of PCP 144V 0 DP

T m ¼ , (14:15)

where e p

D ¼ rotor diameter, in. where

E ¼ rotor=stator eccentricity, in.

P r ¼ pitch length of rotor, ft T m ¼ mechanical resistant torque, lb f -ft

e p ¼ efficiency.

P s ¼ pitch length of stator, ft.

The load on thrust bearing through the drive string is

Two numbers define the geometry of the PCP: the num-

ber of lobes of rotor and the number of lobes of the stator. expressed as

A pump with a single helical rotor and double helical F b ¼ ð 2E þ DÞ DP, (14:16)

2

stator is described as a ‘‘1-2 pump’’ where P s ¼ 2P r . For 4

a multilobe pump, where F b ¼ axial load, lb f .

L r þ 1

P s ¼ P r , (14:11)

14.4.2 Selection of Down-Hole PCP

L r

where L r is the number of rotor lobes. The ratio P r =P s is The following procedure can be used in the selection of a

called the ‘‘kinematics ratio.’’ PCP:

Pump displacement is defined by the fluid volume pro-

duced in one revolution of the rotor: 1. Starting from well IPR, select a desirable liquid flow

rate q Lp at pump depth and the corresponding pump

V 0 ¼ 0:028DEP s , (14:12) intake pressure below the pump p pi .

3

where V 0 ¼ pump displacement, ft . 2. Based on manufacturer’s literature, select a PCP

Pump flow rate is expressed as that can deliver liquid rate Q Lp , where Q Lp > q Lp .

Obtain the value of head rating for an elementary

Q c ¼ 7:12DEP s N Q s , (14:13) cavity dp.

where 3. Determine the required pump discharge pressure p pd

Q c ¼ pump flow rate, bbl/day based on wellhead pressure, tubing size, flow rate Q Lp ,