Page 221 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 221

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap14 Final Proof page 217 3.1.2007 9:10pm Compositor Name: SJoearun

OTHER ARTIFICIAL LIFT METHODS 14/217

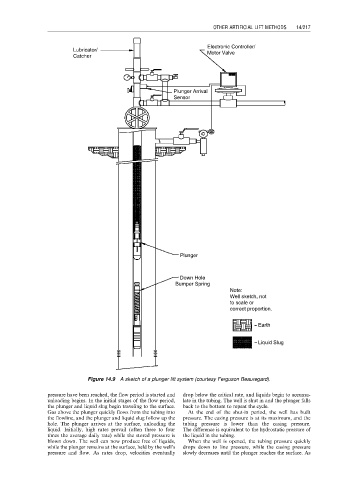

Electronic Controller/

Lubricator/ Motor Valve

Catcher

Plunger Arrival

Sensor

Plunger

Down Hole

Bumper Spring

Note:

Well sketch, not

to scale or

correct proportion.

Earth

Liquid Slug

Figure 14.9 A sketch of a plunger lift system (courtesy Ferguson Beauregard).

pressure have been reached, the flow period is started and drop below the critical rate, and liquids begin to accumu-

unloading begins. In the initial stages of the flow period, late in the tubing. The well is shut in and the plunger falls

the plunger and liquid slug begin traveling to the surface. back to the bottom to repeat the cycle.

Gas above the plunger quickly flows from the tubing into At the end of the shut-in period, the well has built

the flowline, and the plunger and liquid slug follow up the pressure. The casing pressure is at its maximum, and the

hole. The plunger arrives at the surface, unloading the tubing pressure is lower than the casing pressure.

liquid. Initially, high rates prevail (often three to four The difference is equivalent to the hydrostatic pressure of

times the average daily rate) while the stored pressure is the liquid in the tubing.

blown down. The well can now produce free of liquids, When the well is opened, the tubing pressure quickly

while the plunger remains at the surface, held by the well’s drops down to line pressure, while the casing pressure

pressure and flow. As rates drop, velocities eventually slowly decreases until the plunger reaches the surface. As