Page 213 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 213

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap14 Final Proof page 209 3.1.2007 9:10pm Compositor Name: SJoearun

OTHER ARTIFICIAL LIFT METHODS 14/209

the ESP, sensing such conditions as overload, well pump-

off, short in cable, and so on. It also shuts down or starts

up in response to down-hole pressure switches, tank levels,

or remote commands. These controllers are available in

conventional electromechanical or solid-state devices.

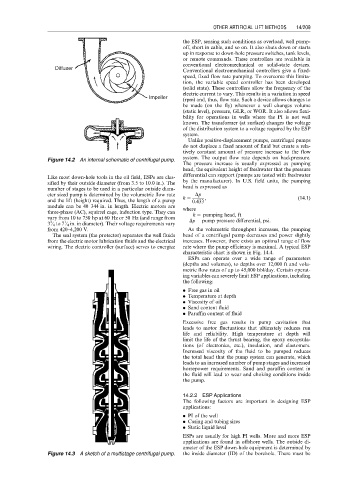

Diffuser

Conventional electromechanical controllers give a fixed-

speed, fixed flow rate pumping. To overcome this limita-

tion, the variable speed controller has been developed

(solid state). These controllers allow the frequency of the

electric current to vary. This results in a variation in speed

Impeller

(rpm) and, thus, flow rate. Such a device allows changes to

be made (on the fly) whenever a well changes volume

(static level), pressure, GLR, or WOR. It also allows flexi-

bility for operations in wells where the PI is not well

known. The transformer (at surface) changes the voltage

of the distribution system to a voltage required by the ESP

system.

Unlike positive-displacement pumps, centrifugal pumps

do not displace a fixed amount of fluid but create a rela-

tively constant amount of pressure increase to the flow

Figure 14.2 An internal schematic of centrifugal pump. system. The output flow rate depends on backpressure.

The pressure increase is usually expressed as pumping

head, the equivalent height of freshwater that the pressure

differential can support (pumps are tested with freshwater

Like most down-hole tools in the oil field, ESPs are clas-

sified by their outside diameter (from 3.5 to 10.0 in.). The by the manufacturer). In U.S. field units, the pumping

number of stages to be used in a particular outside diam- head is expressed as

eter sized pump is determined by the volumetric flow rate Dp

and the lift (height) required. Thus, the length of a pump h ¼ 0:433 , (14:1)

module can be 40–344 in. in length. Electric motors are where

three-phase (AC), squirrel cage, induction type. They can h ¼ pumping head, ft

vary from 10 to 750 hp at 60 Hz or 50 Hz (and range from Dp ¼ pump pressure differential, psi.

3

1

3 ⁄ 4 to 7 ⁄ 4 in. in diameter). Their voltage requirements vary

from 420–4,200 V. As the volumetric throughput increases, the pumping

The seal system (the protector) separates the well fluids head of a centrifugal pump decreases and power slightly

from the electric motor lubrication fluids and the electrical increases. However, there exists an optimal range of flow

wiring. The electric controller (surface) serves to energize rate where the pump efficiency is maximal. A typical ESP

characteristic chart is shown in Fig. 14.4.

ESPs can operate over a wide range of parameters

(depths and volumes), to depths over 12,000 ft and volu-

metric flow rates of up to 45,000 bbl/day. Certain operat-

ing variables can severely limit ESP applications, including

the following:

. Free gas in oil

. Temperature at depth

. Viscosity of oil

. Sand content fluid

. Paraffin content of fluid

Excessive free gas results in pump cavitation that

leads to motor fluctuations that ultimately reduces run

life and reliability. High temperature at depth will

limit the life of the thrust bearing, the epoxy encapsula-

tions (of electronics, etc.), insulation, and elastomers.

Increased viscosity of the fluid to be pumped reduces

the total head that the pump system can generate, which

leads to an increased number of pump stages and increased

horsepower requirements. Sand and paraffin content in

the fluid will lead to wear and choking conditions inside

the pump.

14.2.2 ESP Applications

The following factors are important in designing ESP

applications:

. PI of the well

. Casing and tubing sizes

. Static liquid level

ESPs are usually for high PI wells. More and more ESP

applications are found in offshore wells. The outside di-

ameter of the ESP down-hole equipment is determined by

Figure 14.3 A sketch of a multistage centrifugal pump. the inside diameter (ID) of the borehole. There must be