Page 212 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 212

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap14 Final Proof page 208 3.1.2007 9:10pm Compositor Name: SJoearun

14/208 ARTIFICIAL LIFT METHODS

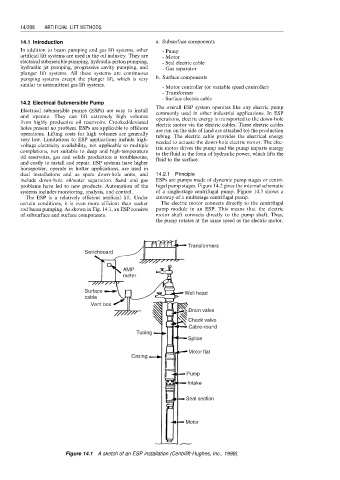

14.1 Introduction a. Subsurface components

In addition to beam pumping and gas lift systems, other - Pump

artificial lift systems are used in the oil industry. They are - Motor

electrical submersible pumping, hydraulic piston pumping, - Seal electric cable

hydraulic jet pumping, progressive cavity pumping, and - Gas separator

plunger lift systems. All these systems are continuous

pumping systems except the plunger lift, which is very b. Surface components

similar to intermittent gas lift systems.

- Motor controller (or variable speed controller)

- Transformer

- Surface electric cable

14.2 Electrical Submersible Pump

The overall ESP system operates like any electric pump

Electrical submersible pumps (ESPs) are easy to install commonly used in other industrial applications. In ESP

and operate. They can lift extremely high volumes operations, electric energy is transported to the down-hole

from highly productive oil reservoirs. Crooked/deviated electric motor via the electric cables. These electric cables

holes present no problem. ESPs are applicable to offshore are run on the side of (and are attached to) the production

operations. Lifting costs for high volumes are generally tubing. The electric cable provides the electrical energy

very low. Limitations to ESP applications include high- needed to actuate the down-hole electric motor. The elec-

voltage electricity availability, not applicable to multiple tric motor drives the pump and the pump imparts energy

completions, not suitable to deep and high-temperature to the fluid in the form of hydraulic power, which lifts the

oil reservoirs, gas and solids production is troublesome, fluid to the surface.

and costly to install and repair. ESP systems have higher

horsepower, operate in hotter applications, are used in

dual installations and as spare down-hole units, and 14.2.1 Principle

include down-hole oil/water separation. Sand and gas ESPs are pumps made of dynamic pump stages or centri-

problems have led to new products. Automation of the fugal pump stages. Figure 14.2 gives the internal schematic

systems includes monitoring, analysis, and control. of a single-stage centrifugal pump. Figure 14.3 shows a

The ESP is a relatively efficient artificial lift. Under cutaway of a multistage centrifugal pump.

certain conditions, it is even more efficient than sucker The electric motor connects directly to the centrifugal

rod beam pumping. As shown in Fig. 14.1, an ESP consists pump module in an ESP. This means that the electric

of subsurface and surface components. motor shaft connects directly to the pump shaft. Thus,

the pump rotates at the same speed as the electric motor.

Transformers

Switchboard

AMP

meter

Surface Well head

cable

Vent box

Drain valve

Check valve

Cable-round

Tubing

Splice

Motor flat

Casing

Pump

Intake

Seal section

Motor

Figure 14.1 A sketch of an ESP installation (Centrilift-Hughes, Inc., 1998).