Page 208 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 208

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap13 Final Proof page 204 3.1.2007 9:07pm Compositor Name: SJoearun

13/204 ARTIFICIAL LIFT METHODS

Production Out Production Out Production Out

Gas In Gas In Gas In

Continuous Flow Intermitting Lift

Applications Applications

Open Semi-Closed Closed

a b c

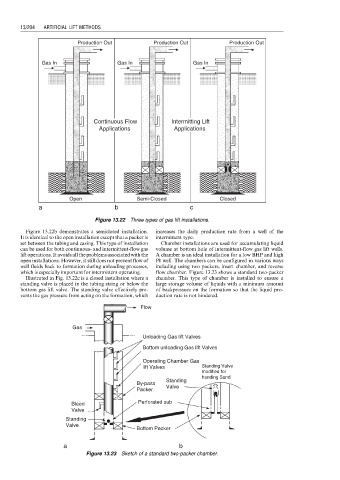

Figure 13.22 Three types of gas lift installations.

Figure 13.22b demonstrates a semiclosed installation. increases the daily production rate from a well of the

It is identical to the open installation except that a packer is intermittent type.

set between the tubing and casing. This type of installation Chamber installations are used for accumulating liquid

can be used for both continuous- and intermittent-flow gas volume at bottom hole of intermittent-flow gas lift wells.

lift operations. It avoids all the problems associated with the A chamber is an ideal installation for a low BHP and high

open installations. However, it still does not prevent flow of PI well. The chambers can be configured in various ways

well fluids back to formation during unloading processes, including using two packers, insert chamber, and reverse

which is especially important for intermittent operating. flow chamber. Figure 13.23 shows a standard two-packer

Illustrated in Fig. 13.22c is a closed installation where a chamber. This type of chamber is installed to ensure a

standing valve is placed in the tubing string or below the large storage volume of liquids with a minimum amount

bottom gas lift valve. The standing valve effectively pre- of backpressure on the formation so that the liquid pro-

vents the gas pressure from acting on the formation, which duction rate is not hindered.

Flow

Gas

Unloading Gas lift Valves

Bottom unloading Gas lift Valves

Operating Chamber Gas

lift Valves Standing Valve

modified for

handing Sand

Standing

By-pass

Valve

Packer

Bleed Perforated sub

Valve

Standing

Valve

Bottom Packer

a b

Figure 13.23 Sketch of a standard two-packer chamber.