Page 209 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 209

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap13 Final Proof page 205 3.1.2007 9:07pm Compositor Name: SJoearun

GAS LIFT 13/205

Flow selection of installation methods. Optimization of existing

gas lift systems is left to Chapter 18.

References

Gas

brown, k.e. The Technology of Artificial Lift Methods,

Unloading Gas lift Vol. 1. Tulsa, OK: PennWell Books, 1977.

Valve brown, k.e. The Technology of Artificial Lift Methods,

Bottom unloading Vol. 2a. Tulsa, OK: Petroleum Publishing Co., 1980.

Gas lift Valve economides, m.j., hill, a.d., and ehig-economides, c.

Petroleum Production Systems. New Jersey: Prentice

Hanger Nipple for Dip Hall PTR, 1994.

tube gilbert, w.e. Flowing and gas-lift well performance. API

Operating Chamber Drill. Prod. Practice 1954.

Gas lift Valve guo, b. and ghalambor, a. Natural Gas Engineering

Handbook. Houston, TX: Gulf Publishing Co., 2005.

Packer katz, d.l., cornell, d., kobayashi, r., poettmann, f.h.,

vary, j.a., elenbaas, j.r., and weinaug, c.f. Handbook

Bleed Port or of Natural Gas Engineering. New York: McGraw-Hill

Valve Publishing Company, 1959.

weymouth, t.r. Problems in Natural Gas Engineering.

Standing Valve

Trans. ASME 1912;34:185.

Problems

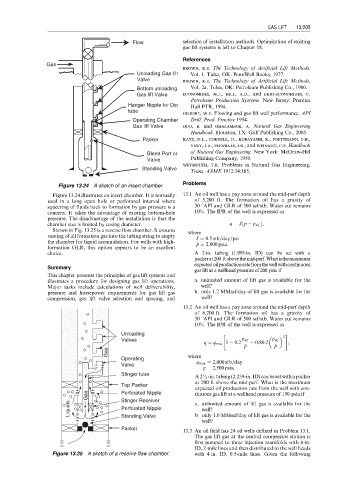

Figure 13.24 A sketch of an insert chamber.

Figure 13.24 illustrates an insert chamber. It is normally 13.1 An oil well has a pay zone around the mid-perf depth

used in a long open hole or perforated interval where of 5,200 ft. The formation oil has a gravity of

squeezing of fluids back to formation by gas pressure is a 30 8API and GLR of 500 scf/stb. Water cut remains

concern. It takes the advantage of existing bottom-hole 10%. The IPR of the well is expressed as

pressure. The disadvantage of the installation is that the

p

chamber size is limited by casing diameter. q ¼ Jb p p wf c,

Shown in Fig. 13.25 is a reverse flow chamber. It ensures where

venting of all formation gas into the tubing string to empty J ¼ 0:5 stb=day=psi

the chamber for liquid accumulation. For wells with high- p p ¼ 2,000 psia.

formation GLR, this option appears to be an excellent

choice. A 2-in. tubing (1.995-in. ID) can be set with a

packerat200 ftabovethemid-perf.Whatisthemaximum

expectedoilproductionratefromthewellwithcontinuous

Summary

gas lift at a wellhead pressure of 200 psia if

This chapter presents the principles of gas lift systems and

illustrates a procedure for designing gas lift operations. a. unlimited amount of lift gas is available for the

Major tasks include calculations of well deliverability, well?

pressure and horsepower requirements for gas lift gas b. only 1.2 MMscf/day of lift gas is available for the

compression, gas lift valve selection and spacing, and well?

13.2 An oil well has a pay zone around the mid-perf depth

of 6,200 ft. The formation oil has a gravity of

30 8API and GLR of 500 scf/stb. Water cut remains

10%. The IPR of the well is expressed as

Unloading " 2 #

Valves p wf p wf

q ¼ q max 1 0:2 0:80:2 ,

p p p p

Gas

Operating where

q max ¼ 2,000 stb=day

Valve

p p ¼ 2,500 psia.

Stinger tube 1

A2 ⁄ 2 -in.tubing(2.259-in.ID)canbesetwithapacker

at 200 ft above the mid-perf. What is the maximum

Top Packer

expected oil production rate from the well with con-

Gas Perforated Nipple tinuous gas lift at a wellhead pressure of 150 psia if

Stinger Receiver

Liquids Perforated Nipple a. unlimited amount of lift gas is available for the

well?

b. only 1.0 MMscf/day of lift gas is available for the

Standing Valve

well?

Packer

13.3 An oil field has 24 oil wells defined in Problem 13.1.

The gas lift gas at the central compressor station is

first pumped to three injection manifolds with 6-in.

ID, 2-mile lines and then distributed to the well heads

Figure 13.25 A sketch of a reserve flow chamber. with 4 in. ID, 0.5-mile lines. Given the following