Page 42 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 42

66131_Ludwig_CH10A 5/30/2001 4:08 PM Page 32

32 Applied Process Design for Chemical and Petrochemical Plants

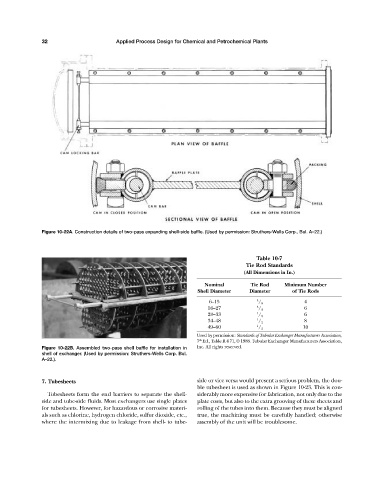

Figure 10-22A. Construction details of two-pass expanding shell-side baffle. (Used by permission: Struthers-Wells Corp., Bul. A–22.)

Table 10-7

Tie Rod Standards

(All Dimensions in In.)

Nominal Tie Rod Minimum Number

Shell Diameter Diameter of Tie Rods

6—15 3 / 8 4

16—27 3 / 8 6

28—33 1 / 2 6

34—48 1 / 2 8

49—60 1 / 2 10

Used by permission: Standards of Tubular Exchanger Manufacturers Association,

th

7 Ed., Table R 4 71, © 1988. Tubular Exchanger Manufacturers Association,

Figure 10-22B. Assembled two-pass shell baffle for installation in Inc. All rights reserved.

shell of exchanger. (Used by permission: Struthers-Wells Corp. Bul.

A–22.).

7. Tubesheets side or vice versa would present a serious problem, the dou-

ble tubesheet is used as shown in Figure 10-23. This is con-

Tubesheets form the end barriers to separate the shell- siderably more expensive for fabrication, not only due to the

side and tube-side fluids. Most exchangers use single plates plate costs, but also to the extra grooving of these sheets and

for tubesheets. However, for hazardous or corrosive materi- rolling of the tubes into them. Because they must be aligned

als such as chlorine, hydrogen chloride, sulfur dioxide, etc., true, the machining must be carefully handled; otherwise

where the intermixing due to leakage from shell- to tube- assembly of the unit will be troublesome.