Page 537 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 537

CHAP TER 1 6. 2 Standard sedan (saloon) – baseline load paths

In practice some rounding errors due to difficulties in this manner. These panels are relatively deep so bending

defining the exact positions of each force may occur. stresses and deflections will be small although stiffening

It should now be noted that windscreen frame (14), at the top and bottom edges will be necessary to prevent

roof panel (15), and backlight (16) SSSs are not subject buckling. The outer sections carrying the shear force will

to any load for this bending case. probably require swaging to prevent shear buckling.

The loading conditions on the front and rear parcel

shelves are once again similar. The front shelf shown in

16.2.2.5 Shear force and bending Fig. 16.2-5(c) is loaded such that in plan view it is

moment diagrams in major components – deflected towards the rear (þve bending moment) while

design implications the rear shelf in Fig. 16.2-5(d) is deflected forward ( ve

bending moment). Both these shelves must have good

Now that the forces on each SSS have been obtained the bending properties in the centre and adequate shear

shear force and bending moment diagrams can be drawn. connections to the sideframe.

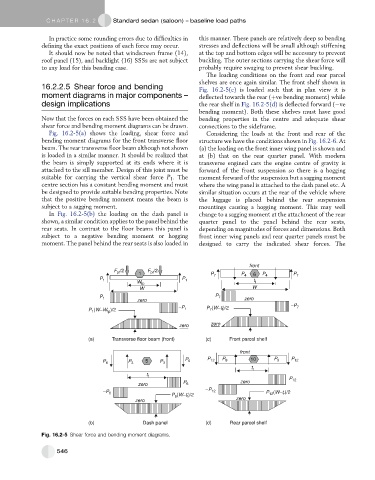

Fig. 16.2-5(a) shows the loading, shear force and Considering the loads at the front and rear of the

bending moment diagrams for the front transverse floor structure we have the conditions shown in Fig. 16.2-6.At

beam. The rear transverse floor beam although not shown (a) the loading on the front inner wing panel is shown and

is loaded in a similar manner. It should be realized that at (b) that on the rear quarter panel. With modern

the beam is simply supported at its ends where it is transverse engined cars the engine centre of gravity is

attached to the sill member. Design of this joint must be forward of the front suspension so there is a hogging

suitable for carrying the vertical shear force P 1 . The moment forward of the suspension but a sagging moment

centre section has a constant bending moment and must where the wing panel is attached to the dash panel etc. A

be designed to provide suitable bending properties. Note similar situation occurs at the rear of the vehicle where

that the positive bending moment means the beam is the luggage is placed behind the rear suspension

subject to a sagging moment. mountings causing a hogging moment. This may well

In Fig. 16.2-5(b) the loading on the dash panel is change to a sagging moment at the attachment of the rear

shown, a similar condition applies to the panel behind the quarter panel to the panel behind the rear seats,

rear seats. In contrast to the floor beams this panel is depending on magnitudes of forces and dimensions. Both

subject to a negative bending moment or hogging front inner wing panels and rear quarter panels must be

moment. The panel behind the rear seats is also loaded in designed to carry the indicated shear forces. The

front

F /2 1 F /2 P P 6 P

pf

pf

P 1 P 1 7 4 t P 4 7

W fp f

W W

P 1 P 7 zero

zero

−P P (W−t f )/2 −P 7

(W−W )/2 1 7

P 1 fp

zero zero

(a) Transverse floor beam (front) (c) Front parcel shelf

front

P 6 P 3 5 P 3 P 6 P 12 P 9 10 P 9 P 12

t r

t f P

P zero 12

zero 6

−P 6 −P 12 P 12 (W−t )/2

r

P 6 (W−t )/2

f

zero zero

(b) Dash panel (d) Rear parcel shelf

Fig. 16.2-5 Shear force and bending moment diagrams.

546