Page 538 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 538

Standard sedan (saloon) – baseline load paths C HAPTER 16.2

I 2 I l

I pt I 1

P 4 P 9

F /2 F /2

l

pt

front

h (iii) P 3 P 8 (vii) rear h 2

1

P 5 P 10

R FL R RL

/2

−F l

P Shear zero

zero 3 force

−F pt /2 −P 8

(I + I )/2 + R I

−F pt pt 1 FL 1

−F (I + I )/2 + R I

2

RL 2

l l

zero zero

Bending

−F I /2 moment −F I /2

pt pt

l l

(a) Front inner wing (b) Rear quarter panel

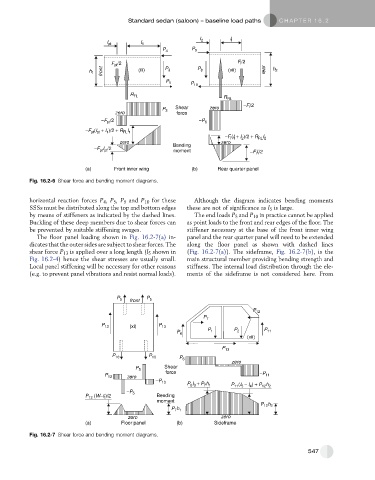

Fig. 16.2-6 Shear force and bending moment diagrams.

horizontal reaction forces P 4 ,P 5 ,P 9 and P 10 for these Although the diagram indicates bending moments

SSSs must be distributed along the top and bottom edges these are not of significance as l 5 is large.

by means of stiffeners as indicated by the dashed lines. The end loads P 5 and P 10 in practice cannot be applied

Buckling of these deep members due to shear forces can as point loads to the front and rear edges of the floor. The

be prevented by suitable stiffening swages. stiffener necessary at the base of the front inner wing

The floor panel loading shown in Fig. 16.2-7(a) in- panel and the rear quarter panel will need to be extended

dicates that the outer sides are subject to shear forces. The along the floor panel as shown with dashed lines

shear force P 13 is applied over a long length (l 5 shown in (Fig. 16.2-7(a)). The sideframe, Fig. 16.2-7(b), is the

Fig. 16.2-4) hence the shear stresses are usually small. main structural member providing bending strength and

Local panel stiffening will be necessary for other reasons stiffness. The internal load distribution through the ele-

(e.g. to prevent panel vibrations and resist normal loads). ments of the sideframe is not considered here. From

P 5 front P 5

P 12

P 7

P 13 (xi) P 13

P 6 P 1 P 2 P 11

(xii)

P 13

P 10 P 10 P 6

zero

P 5 Shear

P 13 zero force −P 11

−P 13 P I + P h P (I − I ) + P h

7 1

6 3

−P 5 11 5 4 12 2

P (W−t )/2 Bending

13

f

moment

P 12 h 2

P h

7 1

zero zero

(a) Floor panel (b) Sideframe

Fig. 16.2-7 Shear force and bending moment diagrams.

547