Page 346 - Biaxial Multiaxial Fatigue and Fracture

P. 346

330 S. POMMIER

Quantitative evaluation of the importance of the load percolation network.

In order to quantify the importance of the formation of a load percolation network for the

fatigue crack nucleation process, the following calculations have been performed. A single

hexagon located at the centre of the thin sheet was set to have a fixed crystal orientation, while

the crystal orientations of the other hexagons in the model were randomly selected before each

calculation. Seventy computations have been performed. For each computation the maximum

principal stress component was determined at the centre of the grain for which the crystal

orientation is fixed. The distribution of this value was calculated for the above seventy random

configurations. This distribution is found to be a Gaussian. Therefore the distribution width is

calculated here, as three times the standard deviation divided by the mean value of the

distribution. The results of these computations are gathered in Table 2. The maximum principal

stress in aluminium is found to vary of +I- 7 % around the mean value. This variability is rather

low as compared with copper and zinc for which the variation is of +I- 35 %. The variability of

the maximum principal stress found for iron, is also very high, Le. +/- 25 %.

It was mentioned in the introduction that two conditions should be hlfilled to promote

fatigue crack nucleation. On the one hand, a “weak” grain should be heavily loaded and on the

other hand, its crystalline orientation should be favourable for slip. It is interesting, at first, to

check if one effect is of prime importance as compared with the other.

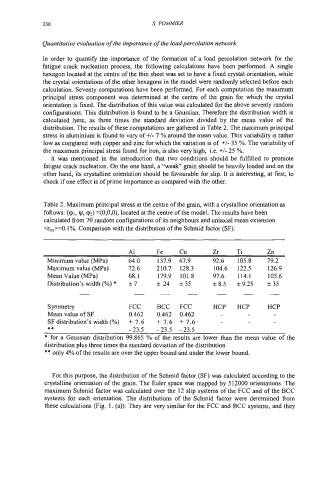

Table 2. Maximum principal stress at the centre of the grain, with a crystalline orientation as

follows: (91, w, (a~) =(O,O,O), located at the centre of the model. The results have been

calculated from 70 random configurations of its neighbours and uniaxial mean extension

-4.1%. Comparison with the distribution of the Schmid factor (SF).

A1 Fe Cu Zr Ti Zn

Minimum value (MPa) 64.0 137.9 67.9 92.6 105.8 79.2

Maximum value (MPa) 72.6 210.7 128.3 104.6 122.5 126.9

Mean Value (MPa) 68.1 179.9 101.8 97.6 114.1 103.6

Distribution’s width (%) * f 7 f 24 S35 k8.5 *9.25 *35

symmetry FCC BCC FCC HCP HCP HCP

Mean value of SF 0.462 0.462 0.462

SF distribution’s width (%) + 7.6 + 7.6 + 7.6

** -23.5 -23.5 -23.5

* for a Gaussian distribution 99.865 % of the results are lower than the mean value of the

distribution plus three times the standard deviation of the distribution

** only 4% of the results are over the upper bound and under the lower bound.

For this purpose, the distribution of the Schmid factor (SF) was calculated according to the

crystalline orientation of the grain. The Euler space was mapped by 512000 orientations. The

maximum Schmid factor was calculated over the 12 slip systems of the FCC and of the BCC

systems for each orientation. The distributions of the Schmid factor were determined from

these calculations (Fig. 1. (a)). They are very similar for the FCC and BCC systems, and they