Page 392 - Boiler_Operators_Handbook,_Second_Edition

P. 392

Controls 377

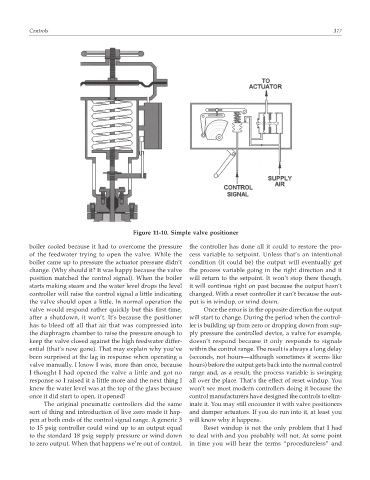

Figure 11-10. Simple valve positioner

boiler cooled because it had to overcome the pressure the controller has done all it could to restore the pro-

of the feedwater trying to open the valve. While the cess variable to setpoint. Unless that’s an intentional

boiler came up to pressure the actuator pressure didn’t condition (it could be) the output will eventually get

change. (Why should it? It was happy because the valve the process variable going in the right direction and it

position matched the control signal). When the boiler will return to the setpoint. It won’t stop there though,

starts making steam and the water level drops the level it will continue right on past because the output hasn’t

controller will raise the control signal a little indicating changed. With a reset controller it can’t because the out-

the valve should open a little. In normal operation the put is in windup, or wind down.

valve would respond rather quickly but this first time, Once the error is in the opposite direction the output

after a shutdown, it won’t. It’s because the positioner will start to change. During the period when the control-

has to bleed off all that air that was compressed into ler is building up from zero or dropping down from sup-

the diaphragm chamber to raise the pressure enough to ply pressure the controlled device, a valve for example,

keep the valve closed against the high feedwater differ- doesn’t respond because it only responds to signals

ential (that’s now gone). That may explain why you’ve within the control range. The result is always a long delay

been surprised at the lag in response when operating a (seconds, not hours—although sometimes it seems like

valve manually. I know I was, more than once, because hours) before the output gets back into the normal control

I thought I had opened the valve a little and got no range and, as a result, the process variable is swinging

response so I raised it a little more and the next thing I all over the place. That’s the effect of reset windup. You

knew the water level was at the top of the glass because won’t see most modern controllers doing it because the

once it did start to open, it opened! control manufacturers have designed the controls to elim-

The original pneumatic controllers did the same inate it. You may still encounter it with valve positioners

sort of thing and introduction of live zero made it hap- and damper actuators. If you do run into it, at least you

pen at both ends of the control signal range. A generic 3 will know why it happens.

to 15 psig controller could wind up to an output equal Reset windup is not the only problem that I had

to the standard 18 psig supply pressure or wind down to deal with and you probably will not. At some point

to zero output. When that happens we’re out of control, in time you will hear the terms “procedureless” and