Page 394 - Boiler_Operators_Handbook,_Second_Edition

P. 394

Controls 379

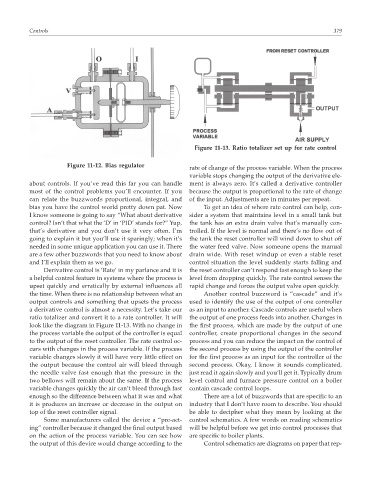

Figure 11-13. Ratio totalizer set up for rate control

Figure 11-12. Bias regulator

rate of change of the process variable. When the process

variable stops changing the output of the derivative ele-

about controls. If you’ve read this far you can handle ment is always zero. It’s called a derivative controller

most of the control problems you’ll encounter. If you because the output is proportional to the rate of change

can relate the buzzwords proportional, integral, and of the input. Adjustments are in minutes per repeat.

bias you have the control world pretty down pat. Now To get an idea of where rate control can help, con-

I know someone is going to say “What about derivative sider a system that maintains level in a small tank but

control? Isn’t that what the ‘D’ in ‘PID’ stands for?” Yup, the tank has an extra drain valve that’s manually con-

that’s derivative and you don’t use it very often. I’m trolled. If the level is normal and there’s no flow out of

going to explain it but you’ll use it sparingly; when it’s the tank the reset controller will wind down to shut off

needed in some unique application you can use it. There the water feed valve. Now someone opens the manual

are a few other buzzwords that you need to know about drain wide. With reset windup or even a stable reset

and I’ll explain them as we go. control situation the level suddenly starts falling and

Derivative control is ‘Rate’ in my parlance and it is the reset controller can’t respond fast enough to keep the

a helpful control feature in systems where the process is level from dropping quickly. The rate control senses the

upset quickly and erratically by external influences all rapid change and forces the output valve open quickly.

the time. When there is no relationship between what an Another control buzzword is “cascade” and it’s

output controls and something that upsets the process used to identify the use of the output of one controller

a derivative control is almost a necessity. Let’s take our as an input to another. Cascade controls are useful when

ratio totalizer and convert it to a rate controller. It will the output of one process feeds into another. Changes in

look like the diagram in Figure 11-13. With no change in the first process, which are made by the output of one

the process variable the output of the controller is equal controller, create proportional changes in the second

to the output of the reset controller. The rate control oc- process and you can reduce the impact on the control of

curs with changes in the process variable. If the process the second process by using the output of the controller

variable changes slowly it will have very little effect on for the first process as an input for the controller of the

the output because the control air will bleed through second process. Okay, I know it sounds complicated,

the needle valve fast enough that the pressure in the just read it again slowly and you’ll get it. Typically drum

two bellows will remain about the same. If the process level control and furnace pressure control on a boiler

variable changes quickly the air can’t bleed through fast contain cascade control loops.

enough so the difference between what it was and what There are a lot of buzzwords that are specific to an

it is produces an increase or decrease in the output on industry that I don’t have room to describe. You should

top of the reset controller signal. be able to decipher what they mean by looking at the

Some manufacturers called the device a “pre-act- control schematics. A few words on reading schematics

ing” controller because it changed the final output based will be helpful before we get into control processes that

on the action of the process variable. You can see how are specific to boiler plants.

the output of this device would change according to the Control schematics are diagrams on paper that rep-