Page 248 - Cam Design Handbook

P. 248

THB8 9/19/03 7:25 PM Page 236

236 CAM DESIGN HANDBOOK

Weight Output

force torque

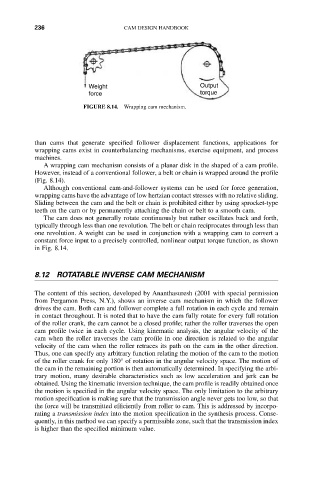

FIGURE 8.14. Wrapping cam mechanism.

than cams that generate specified follower displacement functions, applications for

wrapping cams exist in counterbalancing mechanisms, exercise equipment, and process

machines.

A wrapping cam mechanism consists of a planar disk in the shaped of a cam profile.

However, instead of a conventional follower, a belt or chain is wrapped around the profile

(Fig. 8.14).

Although conventional cam-and-follower systems can be used for force generation,

wrapping cams have the advantage of low hertzian contact stresses with no relative sliding.

Sliding between the cam and the belt or chain is prohibited either by using sprocket-type

teeth on the cam or by permanently attaching the chain or belt to a smooth cam.

The cam does not generally rotate continuously but rather oscillates back and forth,

typically through less than one revolution. The belt or chain reciprocates through less than

one revolution. A weight can be used in conjunction with a wrapping cam to convert a

constant force input to a precisely controlled, nonlinear output torque function, as shown

in Fig. 8.14.

8.12 ROTATABLE INVERSE CAM MECHANISM

The content of this section, developed by Ananthasuresh (2001 with special permission

from Pergamon Press, N.Y.), shows an inverse cam mechanism in which the follower

drives the cam. Both cam and follower complete a full rotation in each cycle and remain

in contact throughout. It is noted that to have the cam fully rotate for every full rotation

of the roller crank, the cam cannot be a closed profile; rather the roller traverses the open

cam profile twice in each cycle. Using kinematic analysis, the angular velocity of the

cam when the roller traverses the cam profile in one direction is related to the angular

velocity of the cam when the roller retraces its path on the cam in the other direction.

Thus, one can specify any arbitrary function relating the motion of the cam to the motion

of the roller crank for only 180° of rotation in the angular velocity space. The motion of

the cam in the remaining portion is then automatically determined. In specifying the arbi-

trary motion, many desirable characteristics such as low acceleration and jerk can be

obtained. Using the kinematic inversion technique, the cam profile is readily obtained once

the motion is specified in the angular velocity space. The only limitation to the arbitrary

motion specification is making sure that the transmission angle never gets too low, so that

the force will be transmitted efficiently from roller to cam. This is addressed by incorpo-

rating a transmission index into the motion specification in the synthesis process. Conse-

quently, in this method we can specify a permissible zone, such that the transmission index

is higher than the specified minimum value.