Page 240 - Chemical Process Equipment - Selection and Design

P. 240

210 HEAT TRANSFER AND HEAT EXCHANGERS

Noncondensoble

gas outlet

Cooling

water inlet

metric

ensei

Recircu Io t ton

-Condensate

Circulating pipe

I I+, Product

Circdlation & ~~~~sion Feed discharge

inlet

vapor , /ZJ Cooling water

Steam

liquor

inlector Circulation Mot her

Evopototor

suspension

Evaporator crystol lizer Vacuum cooiing crystal lizer Coohg crystal ker

(9)

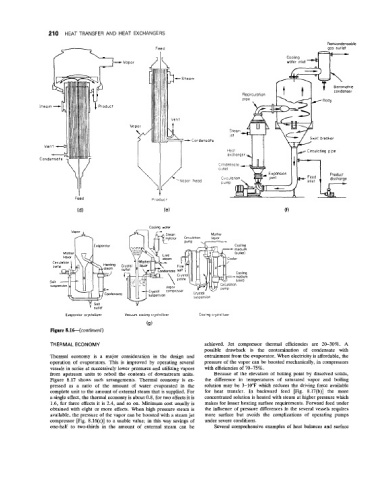

Figure I.lb(continued)

THERMAL ECONOMY achieved. Jet compressor thermal efficiencies are 20-30%. A

possible drawback is the contamination of condensate with

Thermal economy is a major consideration in the design and entrainment from the evaporator. When electricity is affordable, the

operation of evaporators. This is improved by operating several pressure of the vapor can be boosted mechanically, in compressors

vessels in series at successively lower pressures and utilizing vapors with efficiencies of 70-75%.

from upstream units to reboil the contents of downstream units. Because of the elevation of boiling point by dissolved solids,

Figure 8.17 shows such arrangements. Thermal economy is ex- the difference in temperatures of saturated vapor and boiling

pressed as a ratio of the amount of water evaporated in the solution may be 3-10°F which reduces the driving force available

complete unit to the amount of external steam that is supplied. For for heat transfer. In backward feed [Fig. 8.17(b)] the more

a single effect, the thermal economy is about 0.8, for two effects it is concentrated solution is heated with steam at higher pressure which

1.6, for three effects it is 2.4, and so on. Minimum cost usually is makes for lesser heating surface requirements. Forward feed under

obtained with eight or more effects. When high pressure steam is the influence of pressure differences in the several vessels requires

available, the pressure of the vapor can be boosted with a steam jet more surface but avoids the complications of operating pumps

compressor [Fig. 8.16(c)] to a usable value; in this way savings of under severe conditions.

one-half to two-thirds in the amount of external steam can be Several comprehensive examples of heat balances and surface