Page 239 - Chemical Process Equipment - Selection and Design

P. 239

8.10. EVAPORATORS 209

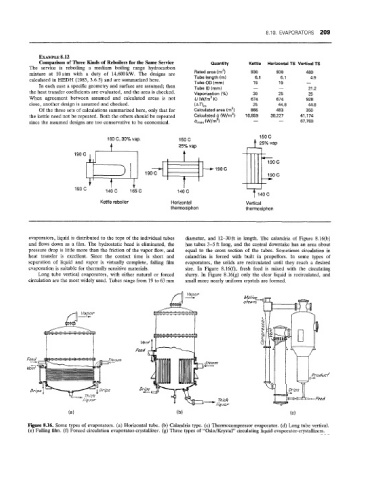

EXAMPLE 8.12:

~o~~~somi Kinds Qf Reboilers foe the Same Service Quantity Kettle Horizontal BS Vertical TS

Three

of

The service is reboiling a medium boiling range hydrocarbon

mixture at lOatm with a duty of 14,600kW. The designs are Rated area (m2) 930 930 480

4.9

calculated in HE:DH (1983, 3.6.5) and are summarized here. Tube length (m) 6.1 6.1 -

-

In each case a specific geometry and surface are assumed; then Tube OD (mm) 19 19 21.2

-

Tube ID (mm)

the heat transfer coefficients are evaluated, and the area is checked. Vaporization (%) 30 25 25

When agreement between assumed and calculated areas is not U (W/mZ K) 674 674 928

close, another design is assumed and checked. (A TI,,, 25 44.8 44.8

Of the three sets of calculations summarized here, only that for Calculated area (m’) 866 483 350

the kettle need not be repeated. Both the others should be repeated Calculated q (W/rn2) 16,859 30,227 41,1?4

-

since the assumed designs are too conservative to be economical. q,,, (W/m2) 67,760

160 C, 30% vap. 150 C 150 C

25% vap

190 C

19

140C 665C 140 C

Kettle reboiler Horizontal Vertical

thermosighon thermosiphon

evaporators, liquid is distributed to the tops of the individual tubes diameter, and 12-30ft in length. The calandria of Figure 8.16(b)

and flows down as a film. The hydrostatic head is eliminated, the has tubes 3-5ft long, and the central downtake has an area about

pressure drop is little more than the friction of the vapor flow, and equal to the cross section of the tubes. Sometimes circulation in

heat transfer is excellent. Since the contact time is short and calandrias is forced with built in propellors. In some types of

separation of liquid and vapor is virtually complete, falling film evaporators, the solids are recirculated until they reach a desired

evaporation is suitable for thermally sensitive materials. size. In Figure 8.16(f), fresh feed is mixed with the circulating

Long tube vertical evaporators, with either natural or forced slurry. In Figure 8.16(g) only the clear liquid is recirculated, and

circulation are the most widely used. Tubes range from 19 to 63 mm small more nearly uniform crystals are formed.

MOfi

sfea

Fie 8.16. Some types of evaporators. (a) Horizontal tube. (b) Calandria type. (c) Thermocompressor evaporator. (d) Long tube vertical

(e) Falling film. (f) Forced circulation evaporator-crystallizer. (g) Three types of “Oslo/Krystal” circulating liquid evaporator-crystallizers.