Page 241 - Chemical Process Equipment - Selection and Design

P. 241

8.1 1. FIRED HEATERS 211

000

Vapors ti)

I

LL

Z 7CO

N

-

t

?-.

Y-

r

y 60C

+

3

m

+-

5 50C

.-

"

.-

Y-

al

Y-

40C

I

a

Condensate .t

VI

C

Z 30C

+

+ 0

L

- 20c

-

0

- -

>

1 oc

C

1

BGiling temperature, "F

Condensate

Rgme 8.17. Forward and backward of liquid flow with respect to

steam flow in triple-effect evaporators. (a) Forward flow of liquid by

action of pressure differences in the vessels. (b) Backward-pumped

flow of liquid through the vessels.

requirements of multiple effect evaporation are worked out by Kern

(1950). = E 100 ,do ,A0 110 do 1QcJ ,bo Lo 240

SURFACE REClUIWEhAENTS 6 Bo~ling temperature, OF

ib)

The data of Tables 8.4-8.7 and particularly 8.10 for boiling liquids

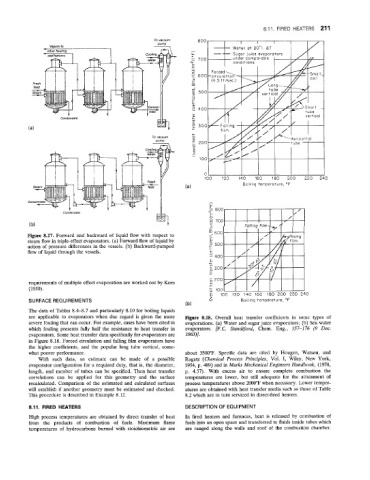

are applicable to evaporators when due regard is given the more Figure 8.18. Overall heat transfer coefficients in some types of

severe fouling that can occur. For example, cases have been cited in evaporations. (a) Water and sugar juice evaporators; (b) Sea water

which fouling presents fully half the resistance to heat transfer in evaporators. IF. C. Standiford, Chem. Eng., 257-1 76 (9 Dec.

evaporators. Some heat transfer data specifically for evaporators are 1963)].

in Figure 8.18. Forced circulation and falling film evaporators have

the higher coefficients, and the popular long tube vertical, some-

what poorer performance. about 3500°F. Specific data are cited by Hougen, Watson, and

With such data, an estimate can be made of a possible Ragatz (Chemical Process Principles, Vol. I, Wiley, New York,

evaporator configuration for a required duty, that is, the diameter, 1954, p. 409) and in Marks Mechanical Engineers Handbook, (1978,

length, and number of tubes can be specified. Then heat transfer p. 4.57). With excess air to ensure complete combustion the

correlations can be applied for this geometry and the surface temperatures are lower, but still adequate for the attainment of

recalculated. Comparison of the estimated and calculated surfaces process temperatures above 2000°F when necessary. Lower temper-

will establish if another geometry must be estimated and checked. atures are obtained with heat transfer media such as those of Table

This procedure is described in Example 8.12. 8.2 which are in turn serviced in direct-fired heaters.

.ll. FIRED HEATER DESCRIPTION OF EQUIPMENT

High process temperatures are obtained by direct transfer of heat In fired heaters and furnaces, heat is released by combustion of

from the products of combustion of fuels. Maximum flame fuels into an open space and transferred to fluids inside tubes which

temperatures otf hydrocarbons burned with stoichiometric air are are ranged along the walls and roof of the combustion chamber.