Page 287 - Defrosting for Air Source Heat Pump

P. 287

Defrosting control strategy 281

Table 9.5 Durations of melted frost downward flowing away from trays

Case no. Circuit 1 (s) Circuit 2 (s) Circuit 3 (s) Average (s)

Case 1 105 90 95 90

Case 2 115 95 105 95

Case 3 120 110 120 110

Case 4 130 120 120 120

Case 5 135 125 135 130

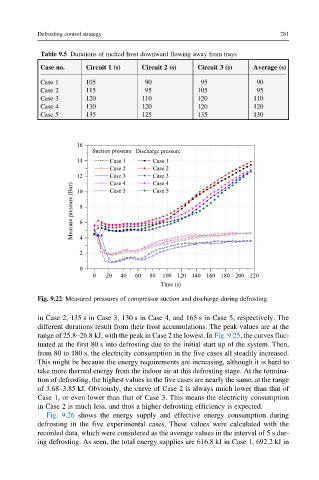

Fig. 9.22 Measured pressures of compressor suction and discharge during defrosting.

in Case 2, 135 s in Case 3, 130 s in Case 4, and 165 s in Case 5, respectively. The

different durations result from their frost accumulations. The peak values are at the

range of 25.8–26.8 kJ, with the peak in Case 2 the lowest. In Fig. 9.25, the curves fluc-

tuated at the first 80 s into defrosting due to the initial start up of the system. Then,

from 80 to 180 s, the electricity consumption in the five cases all steadily increased.

This might be because the energy requirements are increasing, although it is hard to

take more thermal energy from the indoor air at this defrosting stage. At the termina-

tion of defrosting, the highest values in the five cases are nearly the same, at the range

of 3.68–3.85 kJ. Obviously, the curve of Case 2 is always much lower than that of

Case 1, or even lower than that of Case 3. This means the electricity consumption

in Case 2 is much less, and thus a higher defrosting efficiency is expected.

Fig. 9.26 shows the energy supply and effective energy consumption during

defrosting in the five experimental cases. These values were calculated with the

recorded data, which were considered as the average values in the interval of 5 s dur-

ing defrosting. As seen, the total energy supplies are 616.8 kJ in Case 1, 692.2 kJ in