Page 564 - Dynamics of Mechanical Systems

P. 564

0593_C16_fm Page 545 Tuesday, May 7, 2002 7:06 AM

Mechanical Components: Cams 545

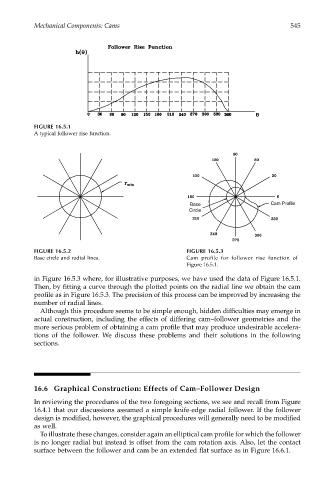

FIGURE 16.5.1

A typical follower rise function.

Base Cam Profile

Circle

FIGURE 16.5.2 FIGURE 16.5.3

Base circle and radial lines. Cam profile for follower rise function of

Figure 16.5.1.

in Figure 16.5.3 where, for illustrative purposes, we have used the data of Figure 16.5.1.

Then, by fitting a curve through the plotted points on the radial line we obtain the cam

profile as in Figure 16.5.3. The precision of this process can be improved by increasing the

number of radial lines.

Although this procedure seems to be simple enough, hidden difficulties may emerge in

actual construction, including the effects of differing cam–follower geometries and the

more serious problem of obtaining a cam profile that may produce undesirable accelera-

tions of the follower. We discuss these problems and their solutions in the following

sections.

16.6 Graphical Construction: Effects of Cam–Follower Design

In reviewing the procedures of the two foregoing sections, we see and recall from Figure

16.4.1 that our discussions assumed a simple knife-edge radial follower. If the follower

design is modified, however, the graphical procedures will generally need to be modified

as well.

To illustrate these changes, consider again an elliptical cam profile for which the follower

is no longer radial but instead is offset from the cam rotation axis. Also, let the contact

surface between the follower and cam be an extended flat surface as in Figure 16.6.1.