Page 263 - Electromechanical Devices and Components Illustrated Sourcebook

P. 263

Chapter 13 Meters 225

Zero Adjustment

Terminal

Permanent Scale Tension Adjustment

Magnet

Zero Lock

Upper Plate

.5 1 1.5

2

VOLTS

Uprights

Suspension

Coil Wire

Needle

Bridge Poles

N

Needle

N S

4 3 2 1 0 1 2 3 4 Scale

S VOLTS

Pivot N S

Pole Faces

Moving Vane Iron Core

Spring Moving Coil

Figure 13-5 Permanent Magnet Galvanometer Preload Permanent

Spring Magnet

Leveling

Terminal Foot

a baseboard and a toy compass is placed on top of a thread

spool in the middle of the coil.

Base

The permanent magnet galvanometer is designed to oper-

ate independent of the earth’s magnetic field. A magnet is Figure 13-7 Moving Coil Galvanometer

added to counter the effects of stray magnetic fields, as shown

in Figure 13-5. When the coil is energized, the instrument’s

field is altered and the needle deflects in direct proportion to

the signal.

When a signal is applied, the coil deflects and the needle indi-

Figure 13-6 shows how to build a permanent magnet gal-

cates the applied voltage. To improve the sensitivity and res-

vanometer. A toy compass is glued to the base of a plastic

olution of these instruments, the needle is often replaced with

box. A curved, magnetized strip is placed around the magnet,

a mirror. A focused light source is reflected off the mirror and

as shown. The coil is then wrapped around the box, compass,

onto a scale located at a distance from the instrument. The

and poles of the magnet. When a signal is applied to the ter-

distance of the scale from the mirror amplifies any movement

minals, the compass needle will deflect.

of the coil.

Moving Coil Voltmeters

Magnetized

Terminal Strip

The most common type of voltmeter is the moving coil design.

This type of meter operates in the same fashion as a moving

Toy Plastic coil galvanometer. The principal difference between the two

Compass Box

instruments is that the voltmeters are generally less sensitive

and considerably more rugged. Their lower sensitivity is gener-

Coil

ally due to the higher resistance of the coil. These instruments

are also more compact than a galvanometer because they are

Terminal

usually mounted into a panel or stand-alone equipment.

Figure 13-8 shows a stylized view of a typical moving coil

Figure 13-6 Bench Built Permanent Magnet Galvanometer

voltmeter. A coil and an iron core are positioned between the

poles of a permanent magnet. The coil/core assembly is

allowed to rotate on two pivot points. A needle, or pointer, is

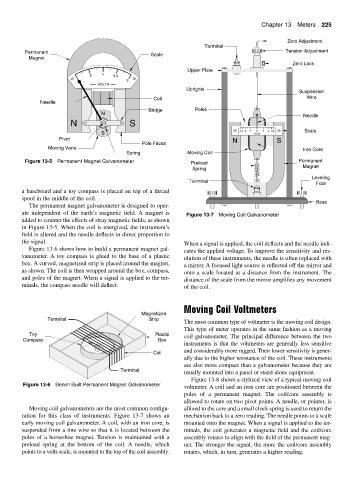

Moving coil galvanometers are the most common configu- affixed to the core and a small clock spring is used to return the

ration for this class of instruments. Figure 13-7 shows an mechanism back to a zero reading. The needle points to a scale

early moving coil galvanometer. A coil, with an iron core, is mounted onto the magnet. When a signal is applied to the ter-

suspended from a fine wire so that it is located between the minals, the coil generates a magnetic field and the coil/core

poles of a horseshoe magnet. Tension is maintained with a assembly rotates to align with the field of the permanent mag-

preload spring at the bottom of the coil. A needle, which net. The stronger the signal, the more the coil/core assembly

points to a volts scale, is mounted to the top of the coil assembly. rotates, which, in turn, generates a higher reading.