Page 214 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 214

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

, ,/

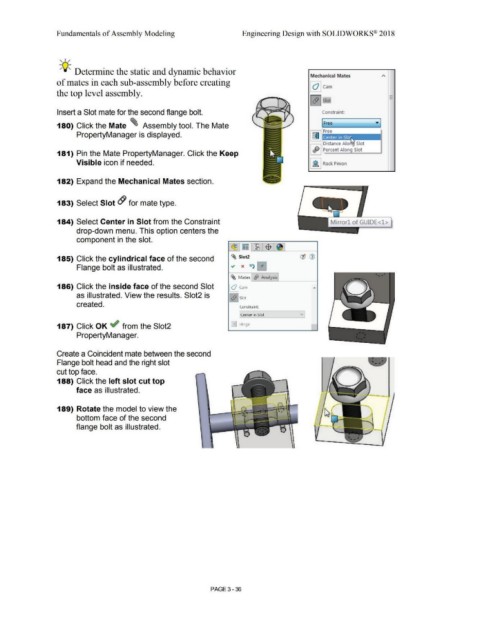

-;Q~ Determine the static and dynamic behavior

Mechanical Mates

of mates in each sub-assembly before creating [Q]cam

the top level assembly. -

-

I (9 j Slot -

Insert a Slot mate for the second flange bolt. Constraint:

180) Click the Mate ~ Assembly tool. The Mate

PropertyManager is displayed. I fill I Fr: e.

Distance Alo Slot

I <ffJ I Percent Along Slot

181) Pin the Mate PropertyManager. Click the Keep

Visible icon if needed. I }l I Rack Pinion

182) Expand the Mechanical Mates section.

183) Select Slot & for mate type.

184) Select Center in Slot from the Constraint

drop-down menu. This option centers the

component in the slot.

~ ~ ~ $ @

-

~ Slot2

185) Click the cylindrical face of the second ., (JJ <i>

Flange bolt as illustrated. x t:t) 'It

~ Mates ~ Analysis

186) Click the inside face of the second Slot lO Jcam "

as illustrated. View the results. Slot2 is

!& !slot

created. Constraint:

Center in Slot vi

,

187) Click OK ~ from the Slot2 lillJ Hinge i

PropertyManager.

Create a Coincident mate between the second

Flange bolt head and the right slot

cut top face.

188) Click the left slot cut top

face as illustrated. -.

189) Rotate the model to view the

bottom face of the second

flange bolt as illustrated. - - -

PAGE 3 - 36