Page 215 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 215

Engineering Design with SOLIDWORKS® 2018 Fundamentals of Assembly Modeling

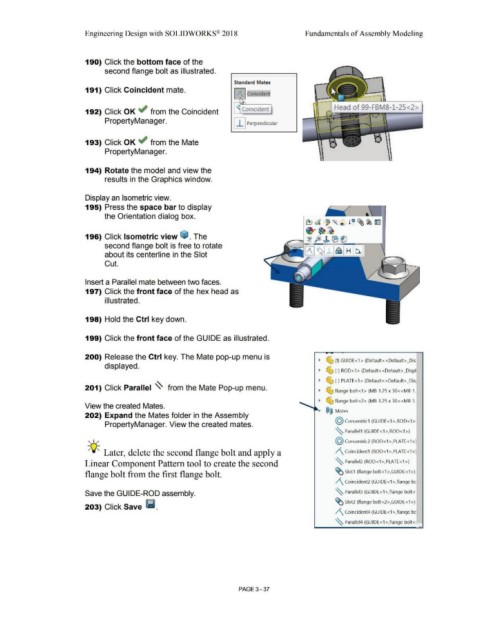

190) Click the bottom face of the

second flange bolt as illustrated.

Standard Mates

191) Click Coincident mate.

.ff Coincident

•

' •

192) Click OK ~ from the Coincident ' Coincident

PropertyManager.

I I I Perpendicular

193) Click OK ~ from the Mate

PropertyManager.

194) Rotate the model and view the

results in the Graphics window.

Display an Isometric view.

195) Press the space bar to display

the Orientation dialog box.

~a '"® !e ~~ ~

~·~~

196) Click Isometric view ~ . The .---.I ~ fe) b ® ei

second flange bolt is free to rotate [/\Jtdj_l~I H 1~1

about its centerline in the Slot

Cut.

Insert a Parallel mate between two faces.

197) Click the front face of the hex head as

i II ustrated.

198) Hold the Ctrl key down.

199) Click the front face of the GUIDE as illustrated.

-

200) Release the Ctrl key. The Mate pop-up menu is

~ ~ (f) GUIDE<1> (Default<<Default>_Dis

displayed.

~ ~ (-) ROD<1> (Default<<Default>_Displ

~ ~ (-) PLATE<1 > (Default<<Default> _Dis1

201) Click Parallel ~ from the Mate Pop-up menu.

~ ~ flange bolt<1 > (M8-1.25 x 30<<M8-1.

~ ~ flange bolt<2> (M8-1 .25 x 30<<M8-1.

View the created Mates.

®@ Mates

202) Expand the Mates folder in the Assembly

@ concentric1 (GUIDE<1 >,ROD<1 >:

PropertyManager. View the created mates.

~ Parallel1 (GUIDE<1 >,ROD<1 >)

, 1 / (Q) Concentric2 (ROD< 1 >,PLATE< 1 >)

-;Q;. Later, delete the second flange bolt and apply a /\_ Coincident1 (ROD<1 >,PLATE<1 >)

Linear Component Pattern tool to create the second ~ Parallel2 (ROD<1 >,PLATE<1 >)

flange bolt from the first flange bolt. ~ Slot1 (flange bolt<1 >,GUIDE<1 >)

/\ Coincident2 (GUIDE<1>,flange be

Save the GUIDE-ROD assembly. ~ Parallel3 (GUIDE<1 >,flange bolt<·

203) Click Save Ii. ~ Slot2 (flange bolt<2>,GUIDE<1 >)

/\ Coincident4 (GUIDE<1 >,flange be

~ Parallel4 {GUIDE<1 >,flange bolt<:

••

PAGE3 - 37