Page 216 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 216

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

, 1 /

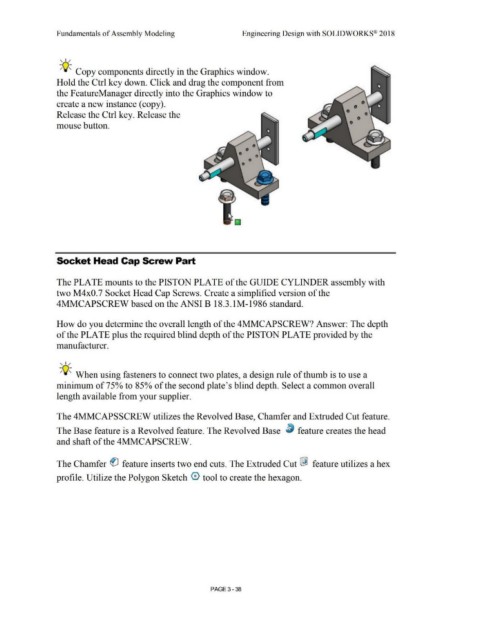

-;Q~ Copy components directly in the Graphics window.

Hold the Ctrl key down. Click and drag the component from

the FeatureManager directly into the Graphics window to

create a new instance (copy).

Release the Ctrl key. Release the

mouse button.

Socket Head Cap Screw Part

The PLATE mounts to the PISTON PLATE of the GUIDE CYLINDER assembly with

two M4x0.7 Socket Head Cap Screws. Create a simplified version of the

4MMCAPSCREW based on the ANSI B 18.3.lM-1986 standard.

How do you determine the overall length of the 4MMCAPSCREW? Answer: The depth

of the PLATE plus the required blind depth of the PISTON PLATE provided by the

manufacturer.

, 1 /

-;Q~ When using fasteners to connect two plates, a design rule of thumb is to use a

minimum of 75% to 85% of the second plate's blind depth. Select a common overall

length available from your supplier.

The 4MMCAPSSCREW utilizes the Revolved Base, Chamfer and Extruded Cut feature.

The Base feature is a Revolved feature. The Revolved Base ~ feature creates the head

and shaft of the 4MMCAPSCREW.

The Chamfer 0 feature inserts two end cuts. The Extruded Cut l&J feature utilizes a hex

profile. Utilize the Polygon Sketch 0 tool to create the hexagon.

PAGE 3 - 38