Page 253 - Failure Analysis Case Studies II

P. 253

23 8

where daldn = fatigue crack growth rate in mm per cycle and AK = stress intensity range = 1.12Ao

,/Z in MPa Jm.

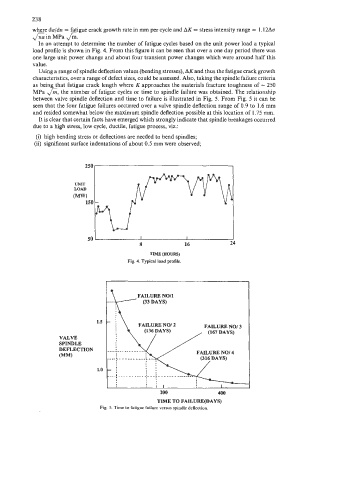

In an attempt to determine the number of fatigue cycles based on the unit power load a typical

load profile is shown in Fig. 4. From this figure it can be seen that over a one day period there was

one large unit power change and about four transient power changes which were around half this

value.

Using a range of spindle deflection values (bending stresses), AKand thus the fatigue crack growth

characteristics, over a range of defect sizes, could be assessed. Also, taking the spindle failure criteria

as bein that fatigue crack length where K approaches the materials fracture toughness of - 250

MPa &, the number of fatigue cycles or time to spindle failure was obtained. The relationship

between valve spindle deflection and time to failure is illustrated in Fig. 5. From Fig. 5 it can be

seen that the four fatigue failures occurred over a valve spindle deflection range of 0.9 to 1.6 mm

and resided somewhat below the maximum spindle deflection possible at this location of 1.75 mm.

It is clear that certain facts have emerged which strongly indicate that spindle breakages occurred

due to a high stress, low cycle, ductile, fatigue process, viz.:

(i) high bending stress or deflections are needed to bend spindles;

(ii) significant surface indentations of about 0.5 mm were observed;

UNIT

LOAD

(MW

150

I I 1

8 16 24

TIME (HOURS)

Fig. 4. Typical load profile.

1.5

FAILURE NO/ 2

VALVE

SPINDLE

DEFLECTION FAILURE NO/ 4

(MM)

1.0

200 400

TIME TO FAIL-AYS)

Fig. 5. Time lo fatigue failure versus spindle deflection.