Page 252 - Failure Analysis Case Studies II

P. 252

23 7

-05

--I

rhread Root

location

Fatigue Crack

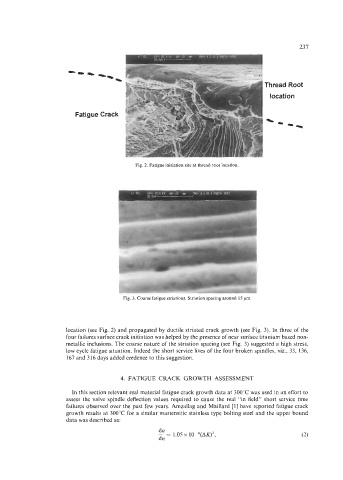

Fig. 2. Fatigue initiation site at thread root location

Fig. 3. Coarse fatigue striations. Striation spacing around 15 pm

location (see Fig. 2) and propagated by ductile striated crack growth (see Fig. 3). In three of the

four failures surface crack initiation was helped by the presence of near surface titanium based non-

metallic inclusions. The coarse nature of the striation spacing (see Fig. 3) suggested a high stress,

low cycle fatigue situation. Indeed the short service lives of the four broken spindles, viz., 33, 136,

167 and 3 16 days added credence to this suggestion.

4. FATIGUE CRACK GROWTH ASSESSMENT

In this section relevant real material fatigue crack growth data at 300°C was used in an effort to

assess the valve spindle deflection values required to cause the real “in field” short service time

failures observed over the past few years. Amzallag and Maillard [l] have reported fatigue crack

growth results at 300°C for a similar martensitic stainless type bolting steel and the upper bound

data was described as:

da

- = 1.05 x 10-6(AK)2,

dn (2)