Page 291 - Fair, Geyer, and Okun's Water and wastewater engineering : water supply and wastewater removal

P. 291

JWCL344_ch07_230-264.qxd 8/2/10 8:44 PM Page 251

7.7 Automated Optimization 251

Chlorine concentration

0.900

0.800

Concentration (mg/L) 0.600

0.700

0.500

0.400

0.300

0.200

0.100

0.000

0.000 24.000 48.000 72.000 96.000 120.000 144.000 168.000

Time (hours)

T-1 J-7 J-2 J-9 J-3

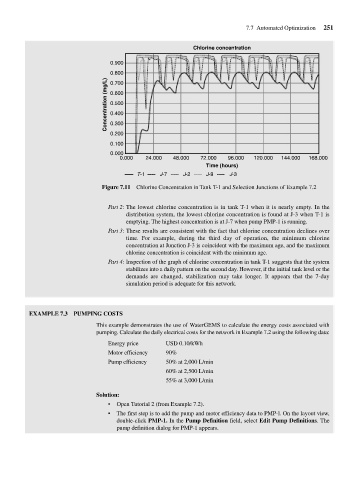

Figure 7.11 Chlorine Concentration in Tank T-1 and Selection Junctions of Example 7.2

Part 2: The lowest chlorine concentration is in tank T-1 when it is nearly empty. In the

distribution system, the lowest chlorine concentration is found at J-3 when T-1 is

emptying. The highest concentration is at J-7 when pump PMP-1 is running.

Part 3: These results are consistent with the fact that chlorine concentration declines over

time. For example, during the third day of operation, the minimum chlorine

concentration at Junction J-3 is coincident with the maximum age, and the maximum

chlorine concentration is coincident with the minimum age.

Part 4: Inspection of the graph of chlorine concentration in tank T-1 suggests that the system

stabilizes into a daily pattern on the second day. However, if the initial tank level or the

demands are changed, stabilization may take longer. It appears that the 7-day

simulation period is adequate for this network.

EXAMPLE 7.3 PUMPING COSTS

This example demonstrates the use of WaterGEMS to calculate the energy costs associated with

pumping. Calculate the daily electrical costs for the network in Example 7.2 using the following data:

Energy price USD 0.10/kWh

Motor efficiency 90%

Pump efficiency 50% at 2,000 L/min

60% at 2,500 L/min

55% at 3,000 L/min

Solution:

• Open Tutorial 2 (from Example 7.2).

• The first step is to add the pump and motor efficiency data to PMP-l. On the layout view,

double-click PMP-1. In the Pump Definition field, select Edit Pump Definitions. The

pump definition dialog for PMP-1 appears.